Car engine overhaul Honda Avancier 1

Replacing the crankshaft pulley and pulley bolt

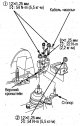

Using the special tool and the TQBX wrench, tighten the crankshaft pulley bolt to the specified torque. Bolt - 16 x 1.5 mm : 245 N·m (25 kg m) Caution: Do not use an impact wrench.

Using the special tool and the TQBX wrench, tighten the crankshaft pulley bolt to the specified torque. Bolt - 16 x 1.5 mm : 245 N·m (25 kg m) Caution: Do not use an impact wrench.

Location of components

Attention: During disassembly, do not use the top and bottom covers to store small parts. Remove dirt with a cloth while installing the covers. Check for oil leaks from the crankshaft and camshaft oil seals and replace...

Attention: During disassembly, do not use the top and bottom covers to store small parts. Remove dirt with a cloth while installing the covers. Check for oil leaks from the crankshaft and camshaft oil seals and replace...

Checking the timing belt

Attention. The crankshaft pulley bolt has a right hand thread. While turning the crankshaft counterclockwise using the pulley bolt, the bolt may loosen. After completing the work, use the TORX key to tighten the...

Attention. The crankshaft pulley bolt has a right hand thread. While turning the crankshaft counterclockwise using the pulley bolt, the bolt may loosen. After completing the work, use the TORX key to tighten the...

Checking the balance shaft belt

Attention. The crankshaft pulley bolt has a right hand thread. When turning the crankshaft counterclockwise with the crankshaft pulley bolt, it may loosen. After completing the work, tighten the crankshaft pulley bolt...

Attention. The crankshaft pulley bolt has a right hand thread. When turning the crankshaft counterclockwise with the crankshaft pulley bolt, it may loosen. After completing the work, tighten the crankshaft pulley bolt...

Adjusting the tension of the timing belt and balancing shaft belt

Attention: Adjustment is carried out on a cold engine (below 38°C). Check the condition of the belts before adjusting the belt tension. Because The belts are tensioned automatically by means of springs, do not apply...

Attention: Adjustment is carried out on a cold engine (below 38°C). Check the condition of the belts before adjusting the belt tension. Because The belts are tensioned automatically by means of springs, do not apply...

Removing the timing belt and balancing shaft belt

Attention. Before removing the timing belt, check the water pump (see below). 1. Disconnect the cables from the battery terminals. Attention: Disconnect the negative terminal first. Before connecting cables, clean the...

Attention. Before removing the timing belt, check the water pump (see below). 1. Disconnect the cables from the battery terminals. Attention: Disconnect the negative terminal first. Before connecting cables, clean the...

Installing the Timing Belt and Balancing Shaft Belt

Installation is carried out in the reverse order of removal, as follows. If only the balancing shaft belt is installed, perform the work starting from point 12. Attention. Before installing the top and bottom covers, be...

Installation is carried out in the reverse order of removal, as follows. If only the balancing shaft belt is installed, perform the work starting from point 12. Attention. Before installing the top and bottom covers, be...

Replacing the TDC / crankshaft sensor

1. Disconnect the cables from the battery terminals. Attention. Disconnect the cable from the negative terminal first. Before connecting the cables, clean the contact surfaces of the terminals with sandpaper and apply...

1. Disconnect the cables from the battery terminals. Attention. Disconnect the cable from the negative terminal first. Before connecting the cables, clean the contact surfaces of the terminals with sandpaper and apply...

Location of cylinder head components

To avoid thermal distortion, remove the cylinder head on a cold engine (below 38°С). Try not to damage the contact surface under the block and cylinder head gasket. Before removing the cylinder head, check the condition...

To avoid thermal distortion, remove the cylinder head on a cold engine (below 38°С). Try not to damage the contact surface under the block and cylinder head gasket. Before removing the cylinder head, check the condition...

Removing the cylinder head

Relieve fuel pressure before removing fuel hose ( see ch. Engine power system ). Take fire safety measures. Do not open the radiator cap on a hot engine. the coolant is under pressure and may splash out. After the...

Relieve fuel pressure before removing fuel hose ( see ch. Engine power system ). Take fire safety measures. Do not open the radiator cap on a hot engine. the coolant is under pressure and may splash out. After the...

Installing the cylinder head

Installation is carried out in the reverse order of removal. Do the following before installation. Replace with new cylinder head and manifold gaskets. Thoroughly clean the mounting surfaces of the cylinder head and...

Installation is carried out in the reverse order of removal. Do the following before installation. Replace with new cylinder head and manifold gaskets. Thoroughly clean the mounting surfaces of the cylinder head and...

Removing the engine

Attention: Be sure to relieve fuel pressure before disconnecting the fuel supply hose ( see ch. Engine power system ). Observe fire safety measures. Do not open the radiator cap on a hot engine. The coolant is under...

Attention: Be sure to relieve fuel pressure before disconnecting the fuel supply hose ( see ch. Engine power system ). Observe fire safety measures. Do not open the radiator cap on a hot engine. The coolant is under...

Engine installation

The engine is installed in the reverse order of removal. To reduce engine noise and vibration and increase bushing life, tighten the engine mounting bolts and nuts as follows. The order of tightening the bolts and nuts...

The engine is installed in the reverse order of removal. To reduce engine noise and vibration and increase bushing life, tighten the engine mounting bolts and nuts as follows. The order of tightening the bolts and nuts...

Diagnostics of malfunctions of the control system of active engine mounts

Make sure that the vacuum hoses and tubes are installed correctly and that there are no defects on them. Before carrying out the following work see ch. Engine management system .

Make sure that the vacuum hoses and tubes are installed correctly and that there are no defects on them. Before carrying out the following work see ch. Engine management system .

Intake manifold replacement

Replace O-rings and gaskets after disassembly.

Replace O-rings and gaskets after disassembly.

Exhaust pipe/silencer replacement

Replace self-locking nuts and gaskets after disassembly. 2WD Models 4WD Models

Replace self-locking nuts and gaskets after disassembly. 2WD Models 4WD Models

Exhaust manifold replacement

Replace self-locking nuts and gaskets after disassembly.

Replace self-locking nuts and gaskets after disassembly.

Selection of main bearings for pistons, crankshaft, cylinders

Attention: When replacing the main bearings, check the marking of the diameters of the crankshaft main journals, the diameters of the holes in the cylinder block and select the necessary bearings from the table. If the...

Attention: When replacing the main bearings, check the marking of the diameters of the crankshaft main journals, the diameters of the holes in the cylinder block and select the necessary bearings from the table. If the...

Selection table for main journals

Indigenous necks №№ 1, 2 Indigenous necks No. 3 Indigenous necks No. 4 Indigenous necks No. 5 The oil clearance for the main journals No. 1, 2 is 0.025-0.049 mm, for the neck No. 3 - 0.021-0.045 mm, for the neck No. 4 -...

Indigenous necks №№ 1, 2 Indigenous necks No. 3 Indigenous necks No. 4 Indigenous necks No. 5 The oil clearance for the main journals No. 1, 2 is 0.025-0.049 mm, for the neck No. 3 - 0.021-0.045 mm, for the neck No. 4 -...

This section is available on: russian, bulgarian, belarusian, ukrainian, serbian, croatian, romanian, polish, slovak, hungarian

Link in different formats to this section

TEXTHTMLBB Code

- General information

- Controls and instruments

- User manual

- Power unit

- Engine maintenance

- Engine repair

- Cooling system

- Engine management

- Power and exhaust system

- Transmission

- Automatic gearbox

- Drive shafts and differential

- Chassis and running gear

- Steering

- Car suspension

- Brake system

- Body and interior

- Doors, locks and windows

- Interior (internal elements)

- Exterior (external elements)

- Air conditioner

- Electrical equipment

- Power devices

- Equipment and devices

- Headlights and lighting

- Electrical circuits

HondaBook.ru © 2018–2024 • Mobile version • Sitemap: EN BG BY UA RS HR RO PL SK HU • Feedback • Driver Information • Search system • Bookmark

Accord 3 (1985-1989) • Accord 6 (1997-2002) • Civic 3 and 4 (1983-1991) • Civic 5 and 6 (1991-2000) • Civic 6 (1995-2000) • Civic 8 (2005-2011) • Fit 1 (2001-2008) • CR-V 1 (1995-2001) • HR-V 1 (1998-2006) • Avancier 1 (1999-2003) •

Accord 3 (1985-1989) • Accord 6 (1997-2002) • Civic 3 and 4 (1983-1991) • Civic 5 and 6 (1991-2000) • Civic 6 (1995-2000) • Civic 8 (2005-2011) • Fit 1 (2001-2008) • CR-V 1 (1995-2001) • HR-V 1 (1998-2006) • Avancier 1 (1999-2003) •