Warning!

- Press the 3rd, 4th and 5th gears onto the countershaft without lubrication.

- When pressing the gears of the 3rd, 4th and 5th gears, install the shaft on steel bars and use a press.

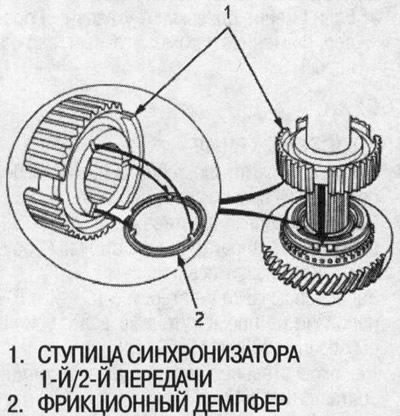

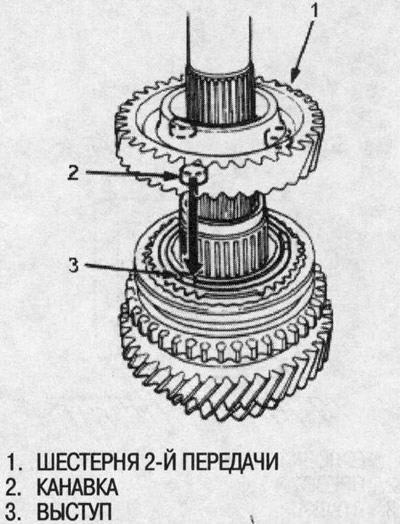

- Press the 3rd, 4th and 5th gears onto the countershaft with a seating force of 9800 N (1000 kgf).

- For final fit, the force must be 925480 N (2600 kgf).

Note: When assembling, refer to the drawing of the intermediate shaft assembly (see above).

1. Install thrust washer, needle bearing, 1st gear and friction damper.

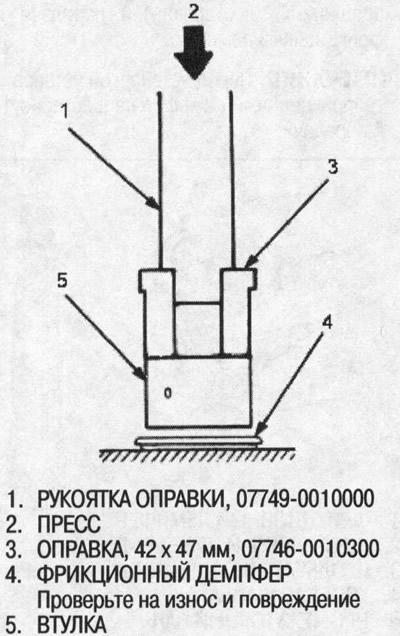

Note: Install the friction damper on the 1st gear before installation.

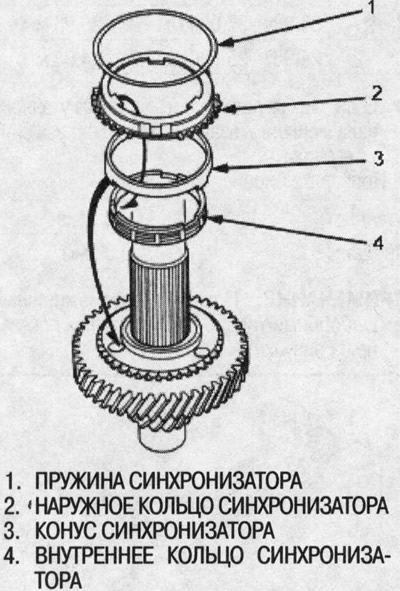

2. Install the double cone synchronizer.

3. Install the 1st/2nd gear synchronizer hub by aligning the tabs on the friction damper with the grooves on the synchronizer hub.

4. Using the special tool, install the friction damper on the bushing and press it in as shown in the figure.

5. Install the 2nd gear by aligning the lugs of the synchronizer cone with the grooves of the 2nd gear.

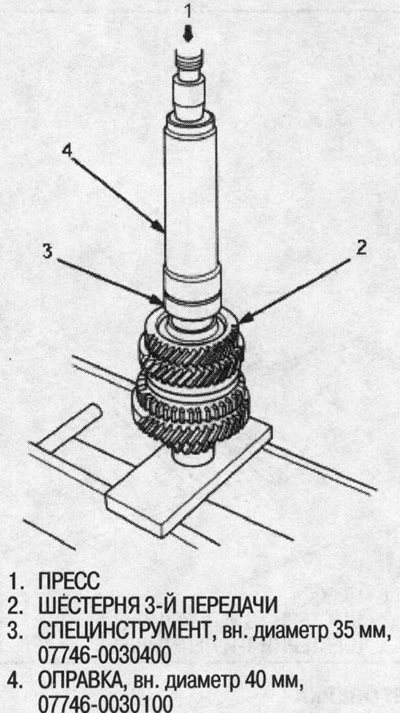

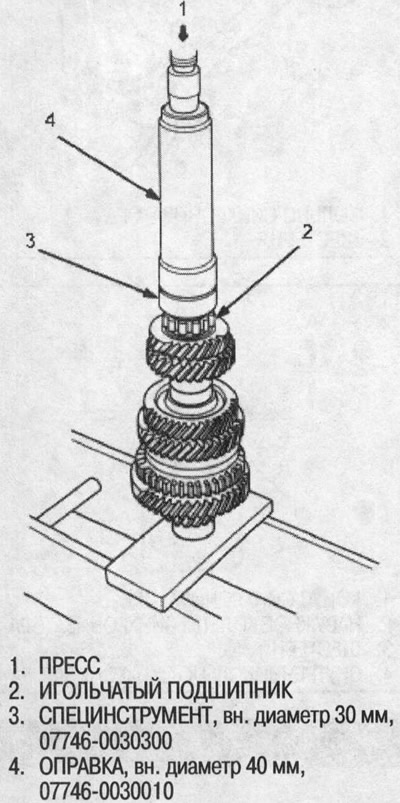

6. Install the intermediate shaft on the steel bars as shown in the figure, use the special tool to install the 3rd gear and press it in as shown in the figure.

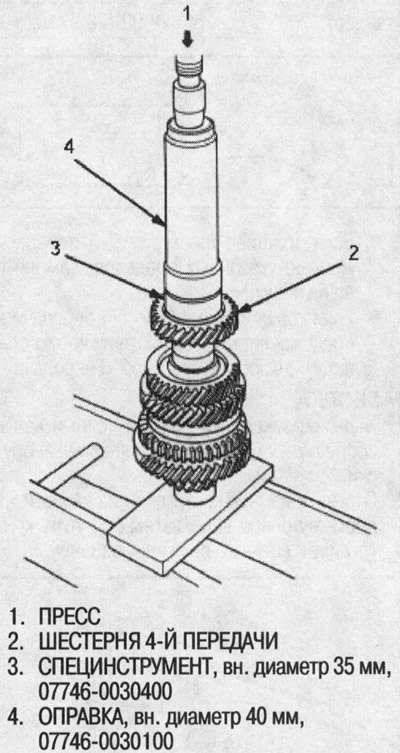

7. Using the special tool, install the 4th gear and press it in as shown.

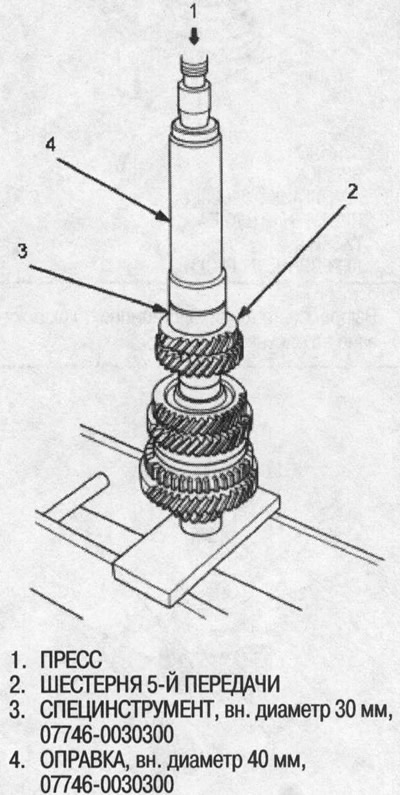

8. Using the special tool, install the 5th gear and press it in as shown.

9. Using the special tool, install the needle bearing and press it in as shown, install the bearing outer race.

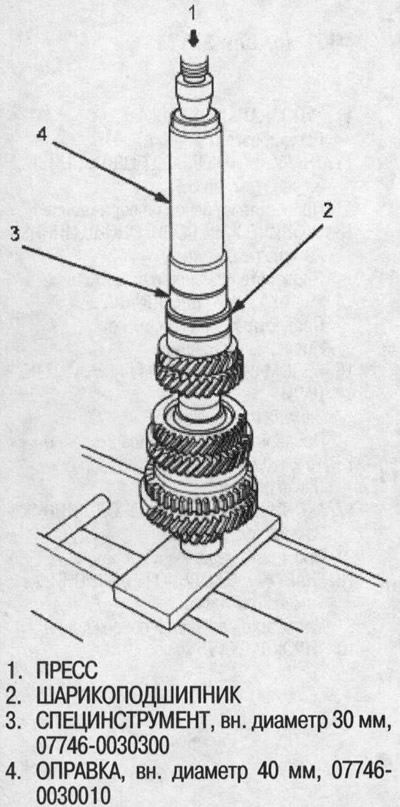

10. Using the special tool, install the ball bearing and press it in as shown.

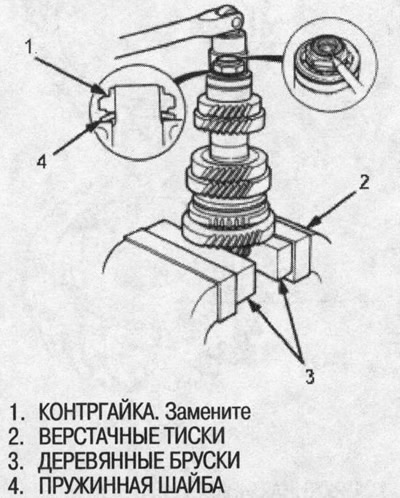

11. Securely secure the intermediate shaft assembly in a vise with blocks of wood.

12. Install spring washer.

13. Install a new lock nut to the correct torque, then caulk the tab of the lock nut into the groove.

Tightening torque: 127-0-127 Nm (13-0-13 kgf/m)