1. Insert the thrust washers on the neck No. 4 of the cylinder block.

2. Insert loose leaves of bearings into a bed of the block of cylinders and on rods.

3. Hold the crankshaft so that the connecting rod journals for cylinders No. 2 and No. 3 are down.

4. Lower the crankshaft into the bed of the cylinder block, seating the connecting rod necks in the connecting rods No. 2 and No. 3, install the covers and tighten the nuts by hand.

5. Rotate the crankshaft clockwise, seat the necks in the No. 1 and No. 4 connecting rods, install the caps and tighten the nuts by hand.

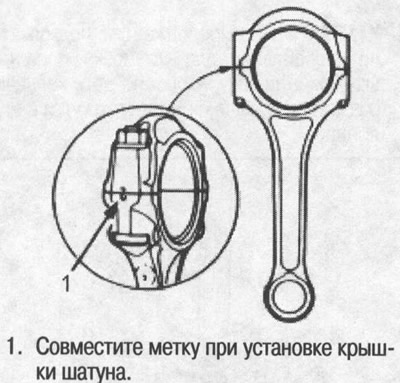

Note: Install the covers so that the notches in the bearings are on the same side as the notches in the connecting rods.

6. Check the clearance in the connecting rod bearing using a Plastigage gauge wire (see above), then tighten the cap nuts to 31 Nm (3.2 kgf/m). Apply engine oil to the bolt threads.

Note: The reference numbers on the connecting rods indicate the diameter of the big end of the connecting rod and are not related to the location of the piston in the engine.

7. Install thrust washers on neck #4. Lubricate the surfaces of the thrust washers with oil.

8. Install the main bearing caps.

9. Check the gap with a calibrated Plastigage wire (see above), then tighten the bearing cap bolts in two passes.

- 1st pass: 25 Nm (2.5 kgf/m)

- 2nd pass: 51 Nm (5.2 kgf/m)

Note: Apply oil to thrust washer surfaces and bolt threads.

Note: When replacing a main or connecting rod bearing, run the engine at idle speed after reassembly until it warms up to normal operating temperature, then about 15 minutes more.

Note:

- Use sealant P/N 08C70-K0234M, 08C70-K0334M, or 08C70-X0331S.

- Make sure contact surfaces are clean and dry before applying sealant.

- Apply sealant evenly, distributing it over the entire contact surface.

- Apply sealant to the threads of the bolt holes to prevent oil leakage.

- Do not install components if more than five minutes have passed since the sealant was applied. Instead, apply sealant again, removing traces of the old.

- After assembly, wait at least 30 minutes before filling the engine with oil.

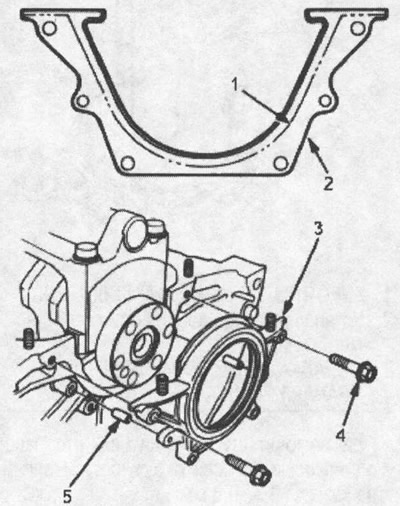

10. Apply sealant to the contact surface of the cylinder block on the side of the right cover, then install it on the cylinder block.

1. Apply sealant along the dotted line.

2. RIGHT COVER

3. RIGHT COVER

4. 6x1.0 mm 11 Nm (1.1 kgf/m)

5. REFERENCE PIN

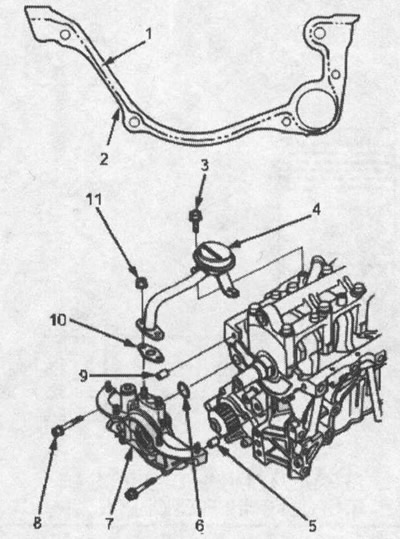

11.Apply sealant to the contact surface of the cylinder block on the oil pump side, then install the oil pump to the cylinder block.

1. Apply sealant along the dotted line.

2. OIL PUMP BODY

3. 3x1.0 mm, 11 Nm (1.1 kgf/m)

4. OIL STRAINER

5. REFERENCE PIN

6. O-ring. Replace.

7. OIL PUMP

8. 6x1.0 mm, 11 Nm (1.1 kgf/m)

9. REFERENCE PIN

10. GASKET. Replace.

11. 6x1.0 mm, 11 Nm (1.1 kgf/m)

Apply grease to the lips of the seals. Then install the oil pump by aligning the inner gear with the crankshaft. After installing the pump, remove excess grease from the crankshaft, then check that the oil seal is not deformed.