21.Press the worm shaft/valve out of the valve body.

22. Check the inside wall in the valve body where the O-ring slides by sticking your finger in. If there is a ledge in the wall, the valve body is worn. Replace valve body.

Note:

- On the wall of the valve body, there may be traces from the sliding of the sealing ring. Replace the valve body only if there is a ledge in the wall.

- When replacing the valve body, place new gaskets on the seating surface of the body and adjust the thickness.

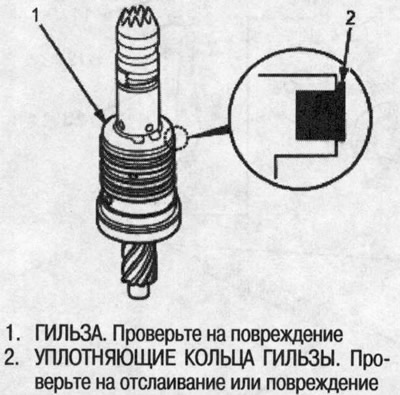

23. Check for wear, burrs or other damage on the edges of the grooves in the sleeve.

Note: Worm shaft and sleeve are matched to each other with a high degree of accuracy. In case of replacement of either the worm shaft or the sleeve, replace them as an assembly.

24. Remove the ring clamp and worm shaft sleeve from the worm shaft.

25. Using a cutter or similar tool, cut and remove the four O-rings from the sleeve. When removing the O-rings, be careful not to damage the edges of the liner grooves and the outer surface.

26. Using a cutter or similar tool, cut off the valve o-ring and o-ring in the groove on the worm shaft. Remove the valve o-ring and O-ring. When removing the valve O-ring and O-ring, be careful not to damage the lip of the groove on the worm shaft and the outer surface.

27. Remove the valve gland and protective ring from the worm shaft. Perform disassembly with the following in mind:

- Check the ball bearing by turning the outer race slowly. If there is excessive play, replace the worm shaft and sleeve assembly.

- Worm shaft and sleeve are fitted to each other with a high degree of accuracy; do not mix old and new worm shafts and sleeves.

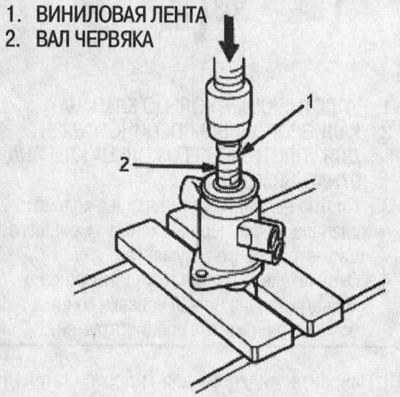

28. Using the special tool, press the valve seal and ball bearing out of the valve body as shown.