Checking the main bearings

1. Clean the main bearings of the cylinder block and crankshaft journals.

2. Place plastic gauges on each crankshaft journal.

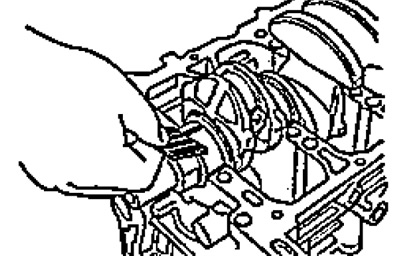

3. Install the main journal bearings and the main bearing cap bridge.

Torque:

- Stage 1 - 25 Nm

- Stage 2 - tighten by 40°

Note: Do not rotate the crankshaft.

4. Remove main covers, bearings and axle covers. Measure the thickness of the plastic gauge at its widest point.

Oil clearance in the main bearing:

- nominal - 0.018 - 0.036 mm

- maximum - 0.050 mm

If the clearance exceeds the maximum, replace the main bearing shells with bearing shells of the same color mark. Check oil clearance.

If the clearance is still not within specification, replace the bearings with larger or smaller bearings (color - labels are given below). Check oil clearance. If the clearance is still not within specification, replace: the crankshaft and check the clearance again.

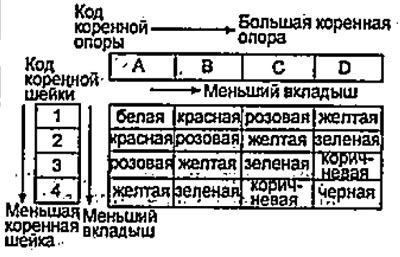

Selection of main bearing shells

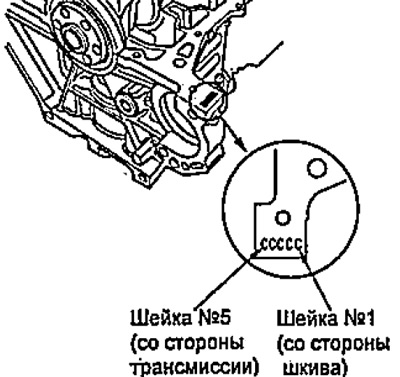

1. The label of the size group of the main neck is stamped on the cylinder block.

If you cannot read the code due to deposits, do not clean the marks with a wire brush, use a solvent.

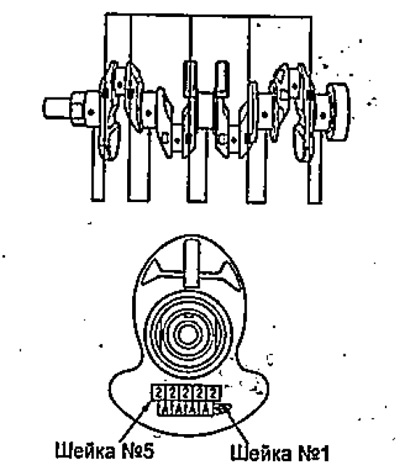

2. The code for the crankshaft main journal is stamped on the crankshaft.

3. According to the table, select the inserts required for replacement.