Checking the traction relay

1. Remove the starter.

2. Remove the cover from the drive side and disconnect the traction relay.

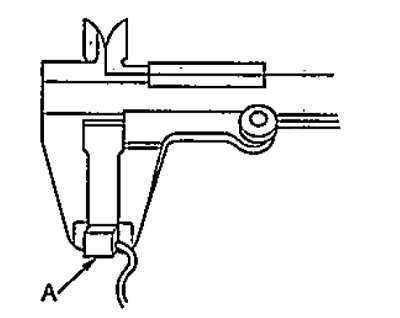

3. Check up resistance between conclusions of the traction relay in two positions.

|  |

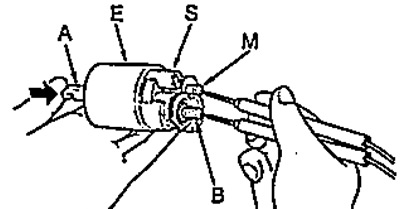

Stator check

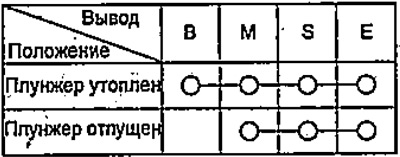

1. Check for continuity between the positive brushes "A" and conclusion "M".

2. Check for continuity between the negative brushes "IN" and hull.

3. Check for continuity between the positive and negative brushes and between the positive brush and housing.

4. Measure the resistance between the brushes and the stator housing with a megger with a rated voltage of 500 V.

- Rated resistance - above 0.01 MΩ

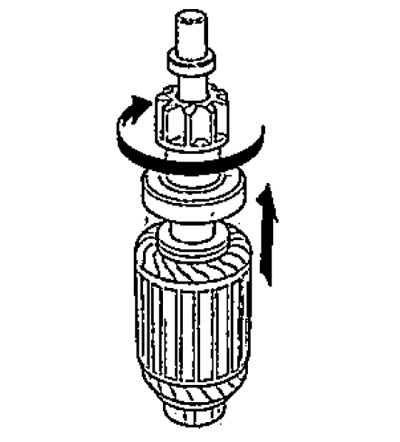

Overrunning clutch test

1. Extend the freewheel and make sure it moves freely. Replace freewheel if defective.

2. Lock the gear and turn the freewheel in the direction shown, making sure it turns freely. Also make sure the clutch locks in the opposite direction, if the clutch does not lock, replace it.

3. Check the gear for wear and damage. If the gear is worn, replace the clutch assembly.

Check the condition of the torque converter ring gear. Replace it if the clutch gear teeth are damaged.

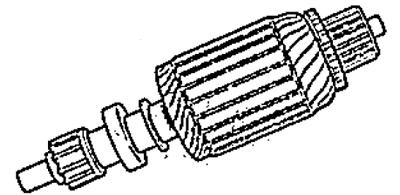

Anchor check

1. Check the anchor for damage and wear.

2. Measure the diameter of the manifold. If it is less than the minimum, replace the anchor.

Collector Diameter:

- nominal - 27.9 - 28.0 mm

- minimum - 27.0 mm

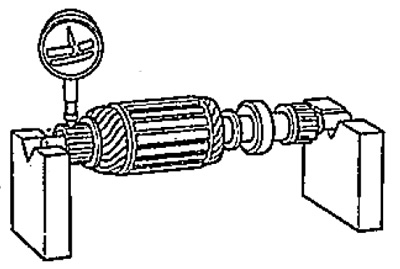

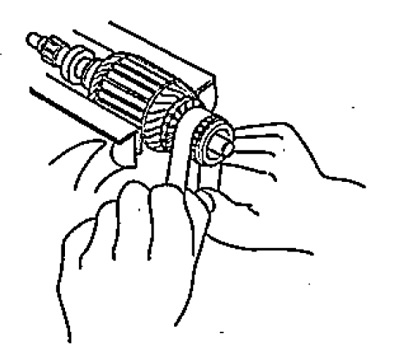

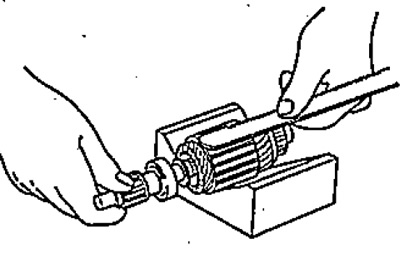

3. Install the anchor on the prisms and check the runout of the collector. If the runout is greater than maximum, replace the armature.

Runout:

- nominal - 0.05 mm

- maximum - 0.40 mm

4. Check the collector surface. If the surface is dirty or has signs of overburning, regrind it with sandpaper (#500, #600) or on a lathe.

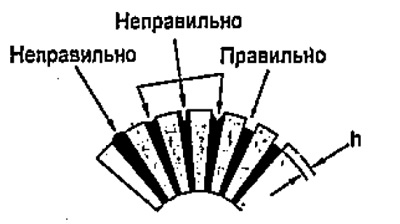

5. Check the protrusion of the collector lamellas. Make grooves with a hacksaw if necessary. Make sure the grooves are deep enough, not too narrow or V-shaped.

Lamella protrusion:

- nominal - 0.45-0.75 mm

- maximum - 0.20 mm

6. Check for continuity between the collector fins. Replace armature if there is no continuity.

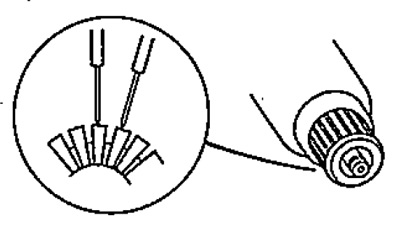

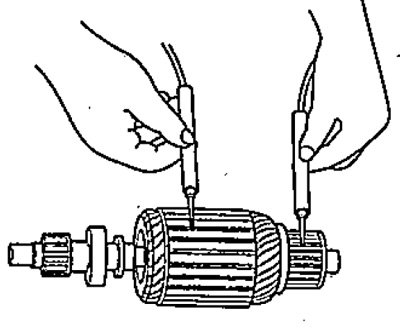

7. Install the anchor on the tester. Fix the hacksaw blade on the anchor core. If the web is attracted to the center or vibration appears when the core is turned, then the armature is shorted. Replace it.

8. Check that there is no continuity between the commutator blades and the armature core, between the commutator blades and the armature shaft.

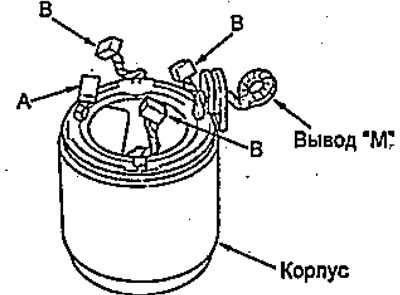

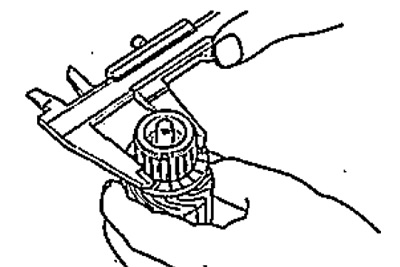

Checking the brushes

Check length, brushes "A". If the brush length is less than the minimum, replace it.

Brush length:

- Nominal length - 9.7- 10.0mm

- Minimum length - 6.0 mm