1. Remove the piston oil cooler nozzle and check it as follows.

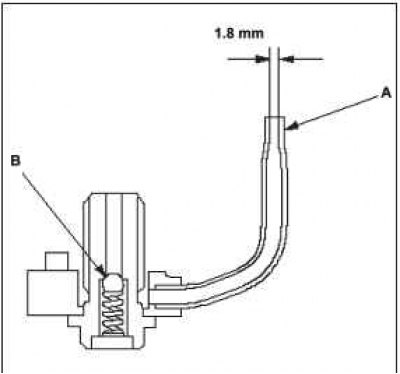

- Make sure the 1.7mm drill goes through oil nozzle hole A (diameter 1.8 mm).

- Insert the other end of the 3.1mm drill into the oil inlet hole (diameter 3.2 mm). Check that check valve ball B moves freely and has a stroke of approximately 2.0 mm.

- Check the operation of the nozzle for oil cooling of the piston using compressed air. A pressure of about 200 kPa should be required (1.2 2.0 kgf/cm2) to move the check valve ball.

Note. Replace the piston oil nozzle assembly if it is broken or bent.

2. Carefully replace the piston oil nozzle. Tightening torque is very important.

Tightening torques: 22 Nm.