2. Remove flywheel/drive plate (see Removal and installation of a flywheel/drive disk).

3. Before removing the old oil seal, be sure to measure the gap between its end surface and the outer edge of the holder (use a small ruler or columbus). Record the results of the measurement - the new oil seal must be planted exactly at the same depth (see part General and overhaul of the engine this Chapter).

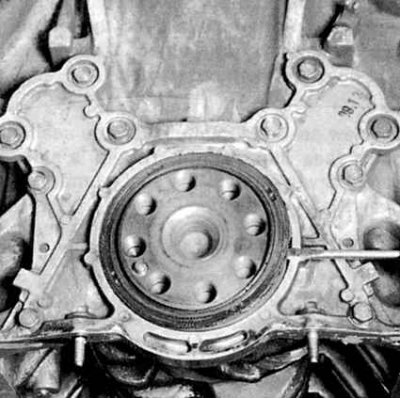

4. The oil seal can be replaced without first dismantling the oil pan and oil seal holder. Carefully prying with a screwdriver, remove the old oil seal from the seat in the holder (see accompanying illustration).

Note. Wrap a rag around the tip of the screwdriver so as not to damage the shaft pin or the socket wall.

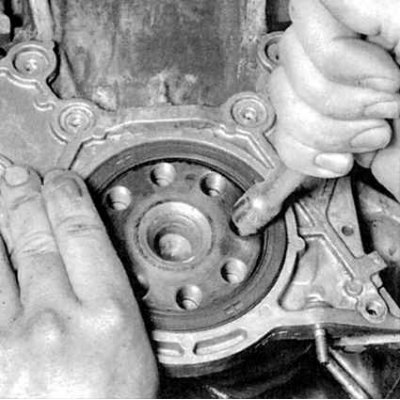

5. Lightly lubricate the edges of the stud and lip of the new oil seal with multipurpose grease, then using a blunt tool, slide the oil seal onto the shaft (see accompanying illustration). Using a mandrel and a hammer, seat the oil seal in the socket (as a mandrel, an end head of the appropriate size can be used, or a piece of pipe of a suitable diameter [slightly smaller than the outer diameter of the stuffing box]).

Note. A description of the procedure for replacing the stuffing box with the dismantling of the holder is given in Part General and overhaul of the engine of this Chapter.

5. Further installation is carried out in the reverse order of dismantling.

6. Start the engine and check for oil leaks.