Note. In the event of leakage, the wheel cylinders must be replaced without fail. Manufacturers do not recommend attempting to refurbish these brake assemblies.

Withdrawal

1. Jack up the rear of the vehicle and place it on jack stands. Support the front wheels with wheel chocks.

2. Remove the brake drum and shoes (see Replacement of shoes of drum brake mechanisms of back wheels).

3. Clean the wheel cylinder and surrounding surfaces from dirt.

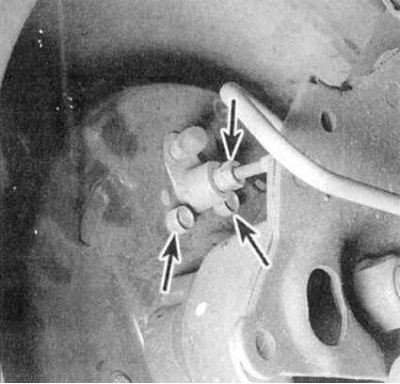

4. Disconnect the hydraulic line from the rear of the wheel cylinder (see accompanying illustration). To avoid rounding of the splines of the fitting, use a special box wrench with a split head. When disconnecting, do not pull on the metal tube of the brake line to avoid its deformation, which can significantly complicate the connection procedure. Seal the open end of the brake line immediately to minimize fluid loss and prevent dirt from entering the hydraulic system.

5. Give two bolts of fastening of the wheel cylinder (see illustration above).

6. Remove the wheel cylinder from the brake shield and transfer it to a clean workbench.

Note. If there are traces of hydraulic fluid on the friction linings of the brake shoes, the shoes should be replaced and the working surface of the drum thoroughly cleaned.

Installation

1. Lubricate mating surfaces of wheel cylinder and brake shield with RTV sealant. Install the cylinder in its proper place and connect the hydraulic line to it. Do not tighten the union nut yet.

2. Screw in the fixing bolts and tighten them firmly. Now you can finally tighten the union nut. Install the shoe assembly in place.

3. Bleed the brake system (see Bleeding the brake system).

4. Before starting the operation of the car, make sure that the brakes are working properly.