Removal/installation

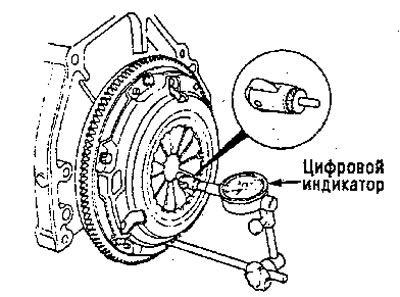

1. Check the height of the diaphragm spring pins using a digital indicator.

Standard (new): 0.8 mm max.

Operational: 1.0 mm limit.

If the height exceeds the operating values, replace the clutch disc.

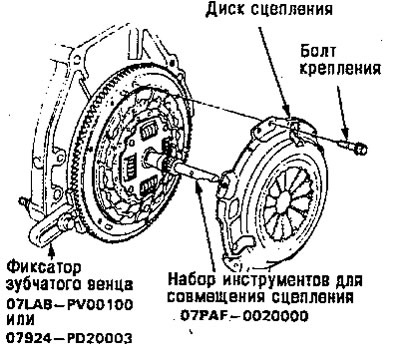

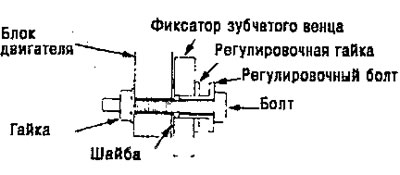

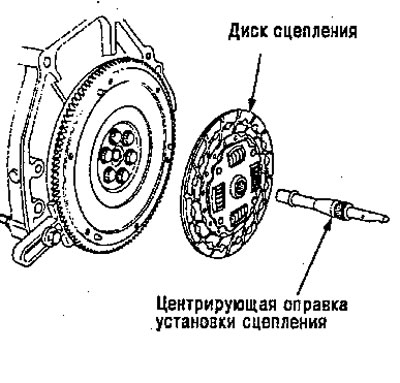

2. Install the special tool as shown.

3. To prevent deformation, unscrew the clutch disc mounting bolts in a criss-cross pattern, then remove the clutch disc.

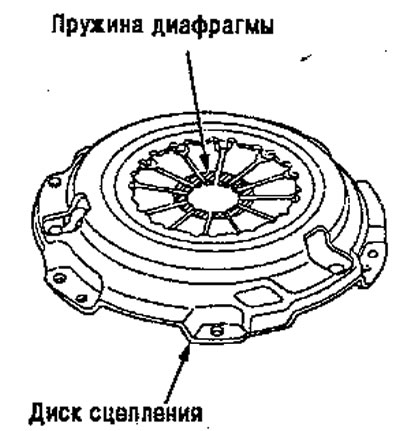

4. Inspect the surface of the clutch disc for wear, cracks and burning.

5. Inspect the diaphragm spring pins for wear in the release bearing contact area.

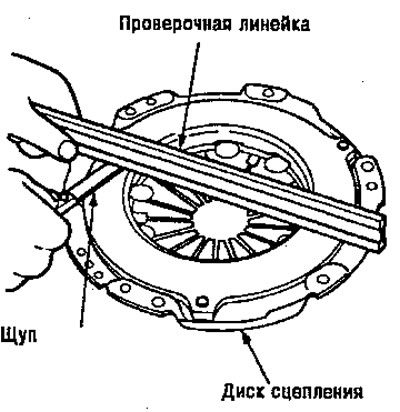

6. Check for deformation using a straight edge and feeler gauge.

Note: Check the clutch pressure plate at three points.

Standard (new): 0.03 mm max.

Operational: 0.15 mm limit.

If the deformation exceeds the operating limits, replace the clutch disc.

Removal/installation

1. Remove the clutch disc and special tools.

2. Inspect the clutch disc lining for signs of slippage or oil. If the clutch disc is burned or soaked in oil, replace it

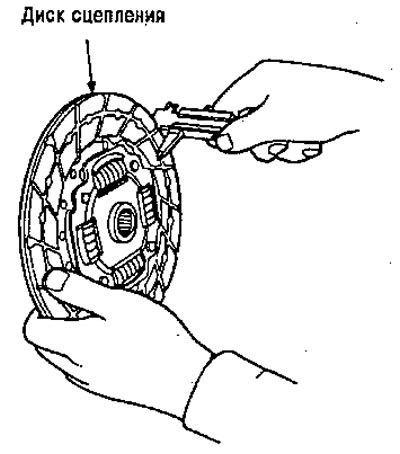

3. Measure the thickness of the clutch disc.

Standard (new):

- Engines V16A2, V16A4, V16A6: 8.4-9.1 mm;

- Engine D16Y7: 8.5-9.1 mm;

- Others: 8.3-9.0 mm.

- Operating limit: 5.5 mm.

If the thickness of the clutch disc is less than the operating values, replace the clutch disc.

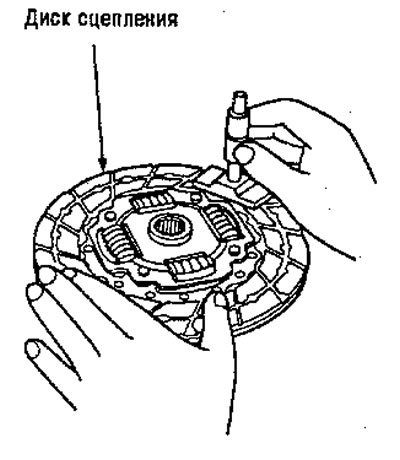

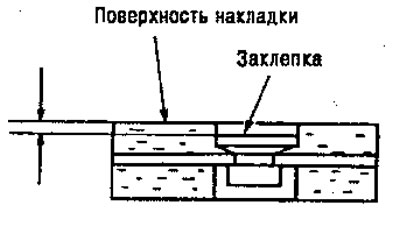

4. Measure the depth from the surface of the trim to the rivet on both sides.

Standard (new):

- Engine D16Y7: 1.3-1.9 mm;

- Other engines: 1.2-1.7 mm;

- Operating limit: 0.2 mm.

If the rivet depth is less than the service value, replace the clutch disc.