Torque converter, gears and clutches.

The torque converter consists of a pump, turbine and reactor combined into one unit. The torque converter is connected to the engine crankshaft, so they rotate together as one unit as the engine rotates. Near the outside of the torque converter is a ring gear that engages the starter when the engine starts. The single torque converter assembly acts as a flywheel, transferring power to the transmission input shaft.

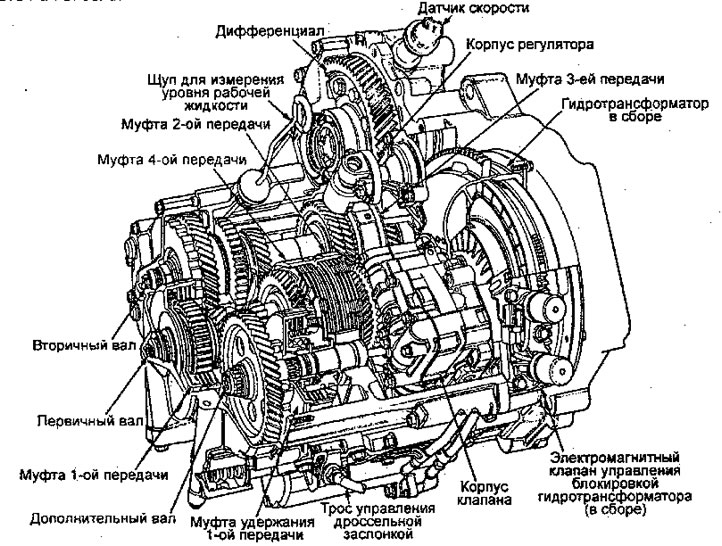

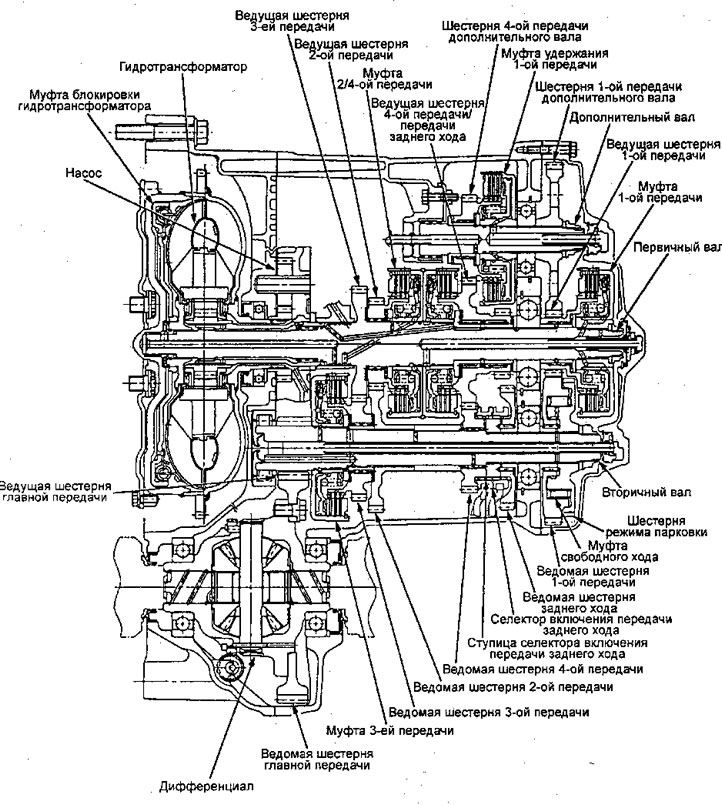

The 7-position transmission has 3 parallel shafts: primary, secondary and auxiliary shaft. The 6-position transmission has two parallel shafts: primary and secondary. The input shaft is located in line with the engine crankshaft. Input shaft includes 1st, 2nd/4th clutches and gears for 3rd, 2nd, 4th, reverse gear and 1st (The 3rd gear is one piece with the input shaft, while the reverse gear is one piece with it. 4th gear). The output shaft includes the 3rd clutch and gears for the 3rd, 2nd, 4th, rear, 1st and parking. The reverse gear and 4th gear can be connected to the center of the output shaft, providing 4th or reverse gears, depending on selector movement. The auxiliary shaft includes a 1st locking clutch and gears for the 1st and 4th.

The gears on the input shaft are in constant engagement with the gears of the secondary shaft. When a particular combination of gears in the transmission is in mesh with the clutches, power is transferred from the input shaft to the output shaft to provide positions [D4], [D3], [2], [1] and [R].

Hydraulic control

Automatic transmission S4PA

The valve assembly includes a main level body, a control valve body, and a control valve body, separated by corresponding separating plates. They are attached to the torque converter housing. The main level body consists of manual control valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, 3-2 timing valve, 4th gear exhaust valve, unloader valve and ATF pump gears. The secondary body consists of a 4-3 relief valve, a jet bypass valve, a 2-3 jet bypass valve, a 2-1 timing valve, a clutch pressure control valve (SRS), servo cylinder control valve, reverse gear control valve, shut-off control valve. The regulator valve body consists of a pressure regulator valve, a lock-up control valve, a torque converter delay valve, and a cooler unload valve.

The servo core consists of a servo cylinder combined with a shift fork shaft, throttle valves A and 8. a 2/3-4 jet bypass valve and batteries.

The modulator valve body, which is fixed on the main body, includes the modulator valve, the locking system valve body includes the locking switching valve and the locking synchronization valve 8 and is fixed on the regulator valve body.

The control valve is mounted on the torque converter housing next to another assembly. Fluid from the regulator passes through the manual valve to the various control valves.

Automatic transmission S4NA

The valve assembly includes a main body, a secondary body, a control valve body and an auxiliary body and an interlock valve body, separated by respective separating plates. They are attached to the torque converter housing. The main level body consists of a manual control valve, shift valve 1-2, 2nd jet control valve, SRV valve, modulator valve, auxiliary control valve, exhaust valve and ATE pump gears. The secondary level body consists of a changeover valve 2-3, changeover valve 3 -4, 3-4 jet control valve, 4th gear exhaust valve and CPG valve (clutch pressure control).

The regulator valve body consists of a pressure regulator valve, a torque converter delay valve, a cooler unload valve, and a lockup control valve. The servo housing consists of a servo cylinder combined with a reverse shift fork and batteries.

The interlock system valve body includes an interlock changeover valve and an interlock timing valve.

Fluid from the regulator passes through the manual valve to the various control valves. The couplings receive fluid from their respective supply channels.

Switching control mechanism.

Locking mechanism

In position [D4], 2nd, 3rd and 4th, and position [D3] in 3rd, pressurized fluid drains from the rear of the torque converter through the fluid passage, causing the piston to be retained on the torque converter cover. When this occurs, the input shaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, engine control unit (ESM) optimizes the synchronization of the mechanism locking.

S4NA

The lock-up control valves control the lock-up range according to throttle position and vehicle speed.

Interlock Timing Valve B controls flow to the Interlock Switching Valve.

The lock-up shut-off valve prevents lock-up from engaging when the throttle valve is not in the appropriate position.

S4PA and S4XA

The lockup control valve controls the lockup range in accordance with the lockup control solenoid valves A and B and the throttle valve B. The lockup control solenoid valves A and B are installed in the torque converter housing and are controlled by the ECM.

S4XA only

Electronics control

The electronics control system consists of a transmission control unit, sensors and 4 solenoid valves. Shifting and locking are electronically controlled for comfortable driving in all conditions. The TCM is located below the instrument panel, behind the driver's side hatch.

Shift Control Mechanism

Input to the TCM from various sensors located throughout the vehicle determines which shift control solenoid valve should be turned on. When the shift control solenoid is turned on, the modulator pressure changes, causing the shift valve to move. This applies line pressure to one of the clutches, engaging that clutch and its associated gear.

Gear selection

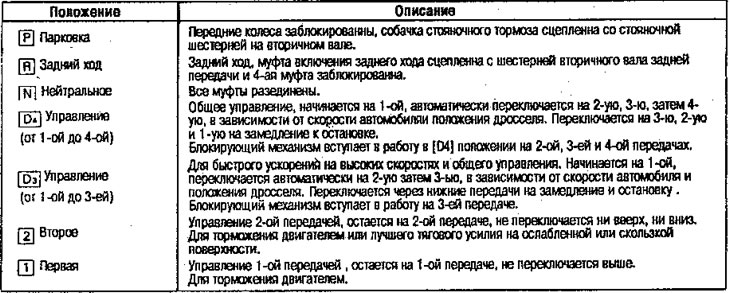

The shift lever has 6 or 7 positions [P] - parking, [R] - reverse, [N] - neutral, [D4] - speeds from 1 to 4, [D3] from 1 to 3, [2]* 2- 1st gear and [1] Van gear.

Starting is only possible in the [P] and [N] positions when using the sliding type safety switch.

A/T position indicator

An indicator shows on the dashboard which gear has been selected without the need to look at the console.

Shown is an automatic transmission with a 7-position shift lever.

On boxes with 6 shift lever positions there are no parts related to the additional shaft.

Couplings

The 4-speed automatic transmission uses hydraulically controlled clutches to engage and disengage the transmission gears. When hydraulic pressure is applied to the clutch drum, the clutch piston moves. This compresses the friction discs and steel plates together, locking them in place» so they don't slip. The power is then transferred through the clutch pack to the hub gear.

When hydraulic pressure is released from the clutch pack, the piston relaxes the friction discs and steel plates so they can move freely relative to each other without transmitting power.

1st clutch

The 1st clutch engages/disengages with the 1st gear and is located at the end of the input shaft, just behind the right side of the cover. The 1st clutch is supplied with hydraulic pressure through the ATF pipe inside the input shaft.

Clutch holding first (7-position transmission)

This clutch is connected in first gear in position [1] to lock the overrunning clutch and provide engine braking. This coupling is located in the middle of the auxiliary shaft and receives pressure through it.

2nd clutch

The 2nd clutch engages/disengages with the 2nd gear and is located in the center of the input shaft. 2nd clutch connected "end to end" with 4th clutch. The 2nd clutch is supplied with hydraulic pressure through the input shaft, along a line connected to the internal hydraulic circuit,

3rd clutch

The 3rd clutch engages/disengages with the 3rd gear and is located at the end of the output shaft opposite the right side of the cover. The 3rd clutch is supplied with hydraulic pressure by the ATF supply tube inside the shaft countershaft.

4th clutch

The 4th clutch engages/disengages with the 4th gear and is located in the center of the input shaft. The 4th coupling is connected to the 2nd coupling. The 4th clutch is supplied with hydraulic pressure by the ATF supply pipe inside the input shaft.

Overrunning clutch

The overrunning clutch is located between the parking gear and the 1st gear of the secondary shaft. The 1st gear of the output shaft provides the outer race surface, and the parking gear provides the inner race surface. The overrunning clutch is locked when power is supplied from the 1st gear of the input shaft to the 1st gear of the output shaft, the 1st clutch and gears remain meshed in 1st, 2nd, 3rd and 4th gears and [ D4], [D3J or [2] position. The overrunning clutch disengages when the 2nd, 3rd or 4th clutch/gear is engaged. This occurs because the increased speed of rotation of the gear on the secondary shaft exceeds the speed of the 1st gear drive.

Accordingly, the overrunning clutch moves freely with the 1st clutch still engaged.

Note: View from the burning right cover

Power flow

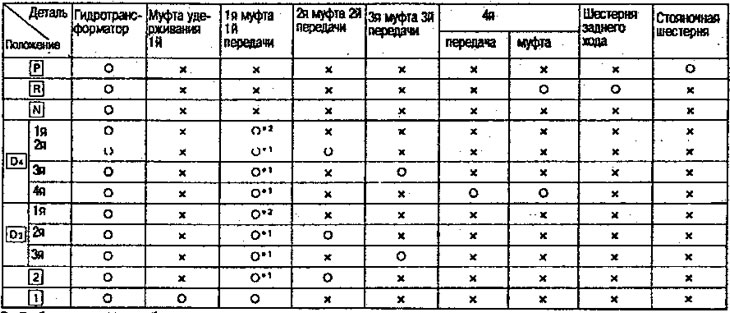

- O: Works x: Doesn't work

- *1: Although the 1st clutch engages, power is not transmitted as the overrunning clutch slips.

- *2: The overrunning clutch engages when accelerating and slips when decelerating.

Note: [1] 1st position and retaining clutch refer to 7 position transmission.

Shown is an automatic transmission with a 7-position shift lever.

On boxes with 6 shift lever positions there are no parts related to the additional shaft.