Leak check

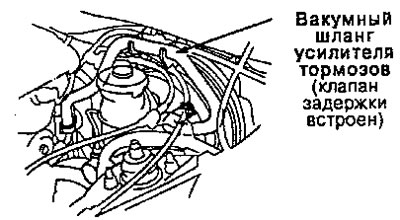

Note: ABS type shown, standard brake type. (9" brake booster) symmetrical

1. Disconnect the brake booster hose from the brake booster, and attach a hose of the appropriate diameter to the brake booster.

2. Install a vacuum gauge between the brake booster vacuum hose and the hose.

Note: The brake booster vacuum hose has a built-in delay control valve.

3. Start the engine, adjust the engine speed with the gas pedal so that the vacuum pressure gauge readings are 40.0 - 66.7 kPa (300-500 mm R.S.), then stop the engine.

4. Look at the vacuum gauge readings.

If the pressure gauge reading decreases to 2.7 kPa (20 mm R.S.) or more after 30 seconds, check the following parts for leaks:

- Control valve

- Vacuum hose, tube

- Oil seals

- Brake booster

- Master brake cylinder

Warning: Do not attempt to disassemble the brake booster. Replace the brake booster as one unit.

Functional check

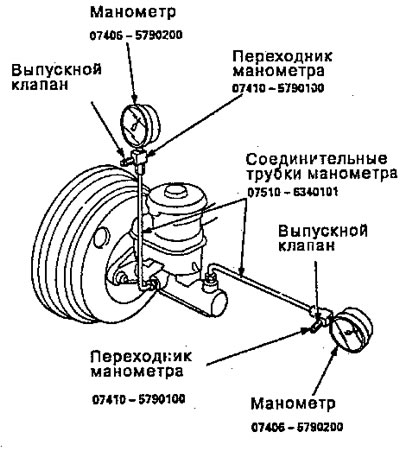

1. Install the vacuum gauge in the same way as for leakage testing.

2. Attach oil pressure gauges to the master cylinder using pressure gauge adapters as shown.

3. Release air through valves

4. Start the engine.

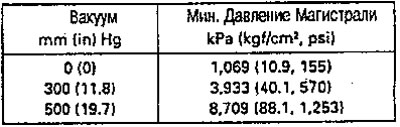

5. Press the brake pedal with a force of 196N (20kgs). The following pressures should be indicated on the pressure gauges at each vacuum level.

Note: The master cylinder size can be set by the 15/16, 7/8 or 13/16 stamps on the master cylinder body.

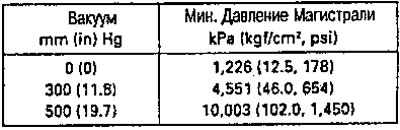

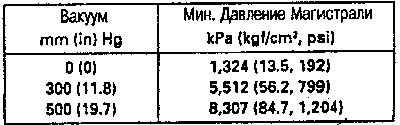

Cars with ABS: 7" + 8" brake booster.

For 14" and 15" Wheel rims (Master brake cylinder ID. 15/16)

For 13" wheel rims (main brake, cylinder, ID 7/8)

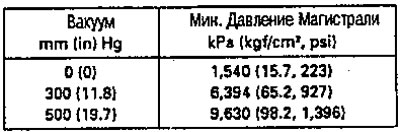

Cars without ABS (standard brake): 9" brake booster

For 14" Wheel rims: (main brake cylinder ID. 7/8)

For 13" wheel disks (main brake cylinder ID. 13/16)

6. Inspect the brake master cylinder for leaks if the readings are not within the limits stated above.

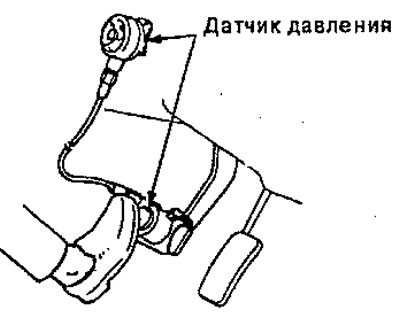

Checking the delay valve.

1. Disconnect the booster vacuum hose

2. Start the engine and let it idle. There must be a vacuum. If there is no vacuum, the delay valve is not working properly. Replace the brake booster vacuum hose and check again.