Checking disc runout

1. Slightly loosen the wheel nuts, then lift the machine and secure it on safe stands. Remove the front wheels.

2. Remove the brake pads.

3. Inspect the surface of the disc for damage and cracks. Clean the disc thoroughly and remove any rust.

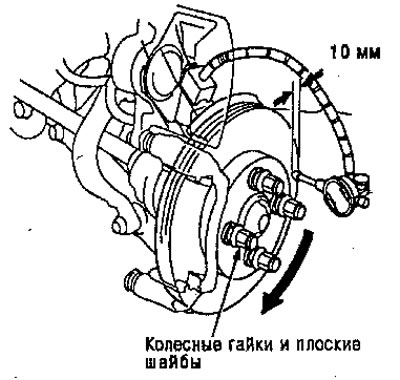

4. Use the wheel nuts and suitable plain washers to press the disc securely to the hub, then attach the digital indicator as shown and measure the runout 10mm from the outer edge of the disc.

Disc runout:

Operational value: 0.10 mm

5. If the disc runout exceeds the operational value, grind the disc.

Limit size after processing: 19 mm

Note: a new disc should be ground if its runout is higher than 0.10 mm.

Checking the thickness of the disc and parallelism of the planes

1. Slightly loosen the front wheel nuts, then jack up the machine and secure it on safe stands. Remove the front wheels.

2. Remove the brake pads.

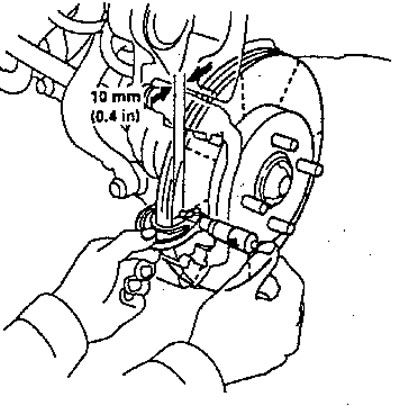

3. Using a micrometer, measure the thickness of the disc at eight points (in about 45") 10 mm deep from the outer edge of the disk.

Brake disc thickness:

Standard: 20.9-21-8 mm

Limit value after processing: 19.0 mm

Note: Replace the brake disc if the smaller dimension is less than the thickness limit.

Deviation of parallelism of planes: 0.015 mm.

Note: This is the maximum allowable difference between thickness measurements.

4. If the disc parallelism deviation exceeds the operational value, grind the disc.