Disassembly - five-speed gearbox

1. Remove the box (see Part 5). Drain the oil if you haven't already. Rinse the box.

2. Remove the bolts and remove the rear cover from the crankcase (see fig. 6.2).

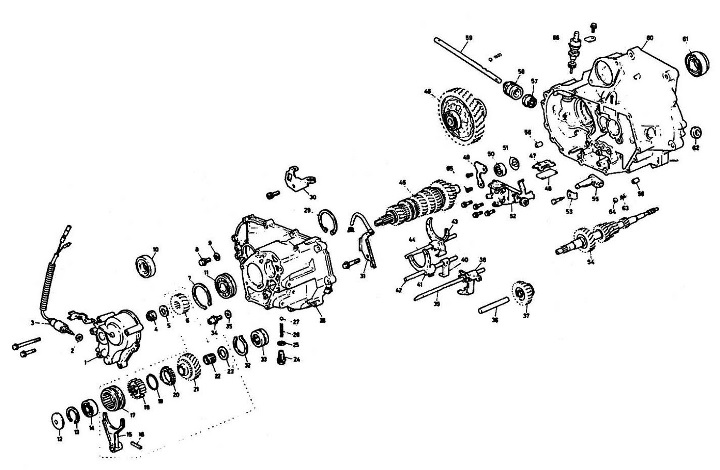

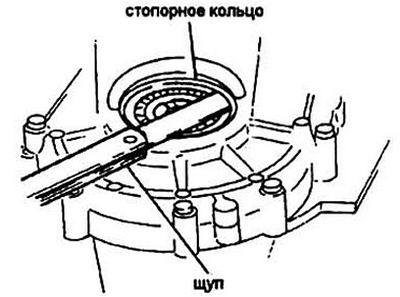

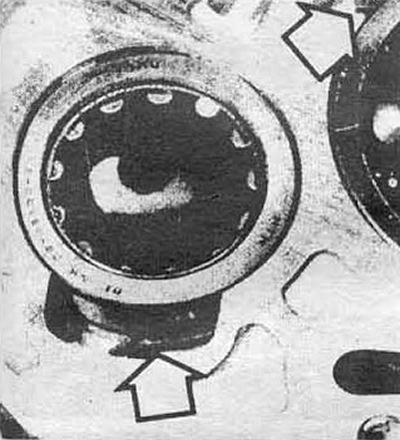

Pic. 6.2 Assembling the 5-speed gearbox

3. Remove the circlip and remove the Belleville washer or flinger (on late models).

4. Take out the bearing of a secondary shaft.

5. Pull out the latch (finger) 5th gear forks.

6. Lower the 5th gear synchronizer sleeve until the gear engages.

7. Pull out the shift fork together with the 5th gear synchronizer clutch.

8. Remove the 5th gear synchronizer sleeve, the synchronizer to the spring.

9. Remove the 5th gear.

10. Remove the needle bearing.

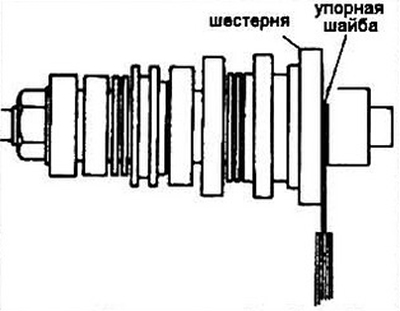

11. Remove the thrust washer.

12. When removing the gear, note both sides. The same goes for the poppet washer. With a tight fit, you can use a puller

13. Unscrew the stopper plugs and remove the springs and balls. Use a magnet to remove the balls.

14. Remove the clutch cable bracket.

15. Turn off bolts of fastening of the case of a box to a flywheel case and remove a box.

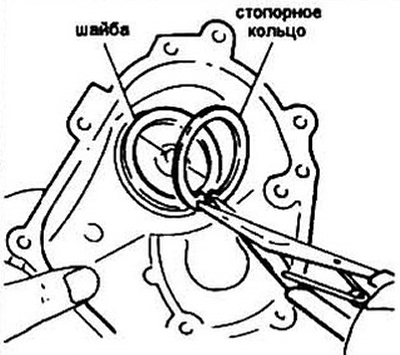

16. Remove the differential seal and remove the circlip from the box crankcase.

17. Remove the circlip and knock out the output shaft and intermediate shaft bearings with a light tap.

18. Move back idler shaft and gear.

19. Turn off a nut of the lever of a gear change of a reverse gear. Remove the special washer and remove the lever that secures the ball and spring. Keep in mind that this ball is larger in diameter than the other three.

20. Bend the lock washer tabs on the three yokes and remove the yoke bolts.

21. Remove the 5th/reverse shift shaft and latch.

22. Remove the shift shaft 1st/2nd gear, then 3rd/4th and latches.

23. Move the 1st/2nd gear synchronizer clutch until it enters the 2nd gear gear and remove the 1st/2nd gear fork.

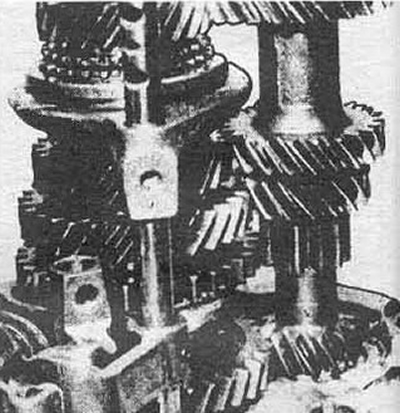

24. Remove a secondary shaft together with intermediate as a whole.

25. Move the shift lever to access the lever holder bolt.

26. Remove the differential/final gear assembly from the flywheel housing.

27. Remove the differential seal.

28. Remove anther and an epiploon of the lever of switching.

29. Turn away bolts of the holder of a drive of a speedometer and remove a drive.

30. Using an impact screwdriver, remove the intermediate shaft bearing retainer screws.

31. Remove the intermediate shaft bearing from the flywheel housing.

32. Remove the oil deflector.

33. Remove the breather assembly from the flywheel housing.

34. Remove the output shaft bearing and oil seal from the flywheel housing four-speed box.

35. Remove the box from the car (see Section 5). Drain the oil if it is not already drained, flush the box.

36. Turn away bolts of fastening of a back cover from the case of a box (see fig. 6.2).

37. Remove retaining ring and remove poppet washer (to early models) or oil deflector (on late models) and the sides of the back cover.

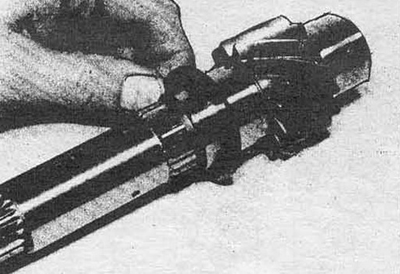

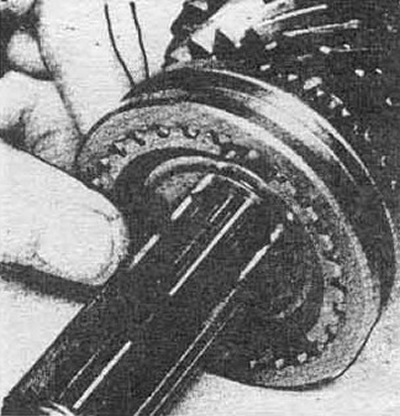

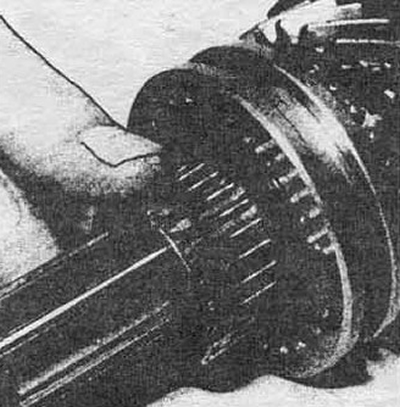

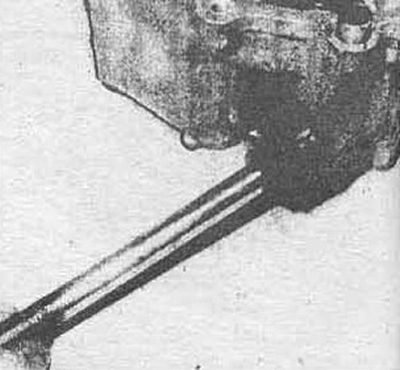

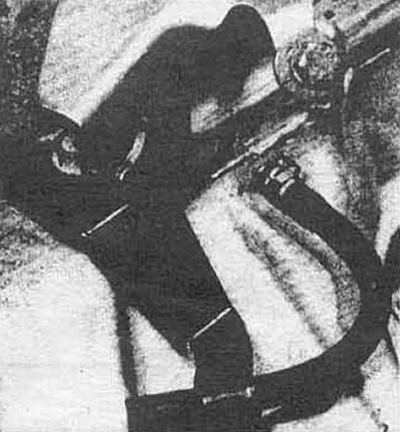

38. Pull the bearing off the intermediate shaft.

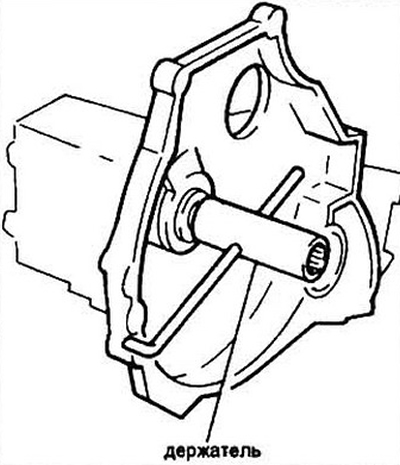

39. Release the limiter and unscrew the intermediate shaft mounting nut. To prevent rotation of the intermediate shaft, hold the secondary shaft with a special holder or a gas key. Do not forget to put a rag under the key lips so that» do not damage the splines.

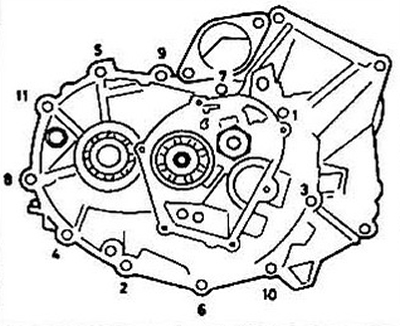

Pic. 6.39 Fitting the output shaft holder 1 - back cover; 2 - washer; 3 - reverse lamp switch; 4 - locknut; 5 - poppet washer; 6 - 5th gear (leading); 7 - retaining ring; 8 - cork; 9 - washer; 10 - differential seal; 11 - intermediate shaft bearing; 12 - oil baffle washer; 13 - stopper; 14 - secondary shaft bearing; 15 - 5th gear engagement fork; 16 - finger; 17 - 5th gear synchronizer plug; 18 - 5th gear synchronizer hub; 19 - synchronizer spring; 20 - synchronizer; 21 - 5th gear (driven); 22 - needle bearing; 23 - thrust washer; 24 - latch cap; 25 - washer; 26 - retainer spring; 27 - retainer ball; 28 - box body; 29 - stopper; 30 - clutch cable bracket; 31 - breather; 32 - stopper; 33 - output shaft bearing; 34 - drain plug; 35 - sealing washer; 36 - shaft of the intermediate reverse gear; 37 - intermediate reverse gear; 38 - latch of the 5th / reverse gear fork; 39 - latch shaft; 40 - latch fork 3rd / 4th gear; 41 - 3rd / 4th gear engagement fork; 42 - fork shaft; 43 - latch fork 1st / 2nd gear; 44 - fork shaft; 45 - intermediate shaft; 46 - differential; 47 - magnet holder; 48 - magnet; 49 - bearing support board; 50 - intermediate shaft bearing; 51 - oil baffle washer; 52 - shift lever holder; 53 - lock washer; 54 - secondary shaft; 55 - switch; 56 - bushing; 57 - switching shaft seal; 58 - anther; 59 - switch shaft; 60 - flywheel housing; 61 - differential seal; 62 - anther; 63 - retainer spring; 64 - retainer ball; 65 - screw; 66 - speedometer drive gear.

40. The remaining steps are identical to those from p. 13 to p. 34. described! Section for removing the 5-speed gearbox.

Intermediate shaft repair (4 and 5 speed boxes)

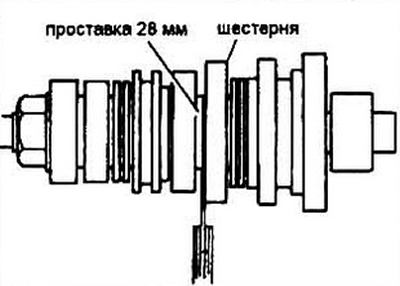

41. Remove the flange spacer.

Pic. 6.41 Assembly of intermediate shaft 1 - synchronizer spring; 2 - synchronizer clutch; 3 - 1st gear; 4 - 1st gear thrust washer (32 mm); 5 - intermediate shaft; 6 - needle bearing; 7 - synchronizer; 8 - synchronizer sleeve; 9 - washer; 10 - spacer 28 mm; 11 - 2nd gear gear; 12 - 3rd gear gear; 13 - gear wheel of the 4th gear; 14 - spacer with a flange; 15 - gear wheel of the 5th gear; 16 - locknut; 17 - disc washer; 18 - retaining ring (65 mm); 19 - bearing.

42. Remove the fourth gear.

43. Remove the synchronizer.

44. Remove the 4th gear needle bearing.

45. Remove the 3rd/4th gear synchronizer.

46. Remove the 3rd gear synchronizer spring.

47. Remove the third gear.

48. Remove the needle bearing and spacer.

49. Remove the washer and second gear.

50. Remove the synchronizer ring and 1st/2nd gear spring.

51. Remove the needle bearing and spacer.

52. Remove the 1st/2nd gear synchronizer assembly. The synchronizer clutch is made together with the reverse gear.

53. Remove the gear, ring and 1st gear synchronizer spring.

54. Remove the needle bearing and thrust washer.

55. Rinse and inspect parts. Replace them if necessary. Lightly oil all parts.

Assembly

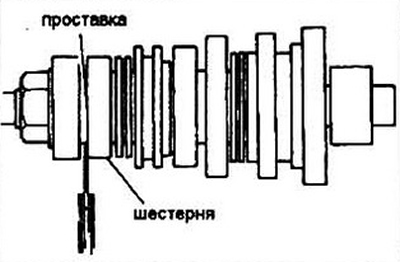

56. Install thrust washer and needle bearing.

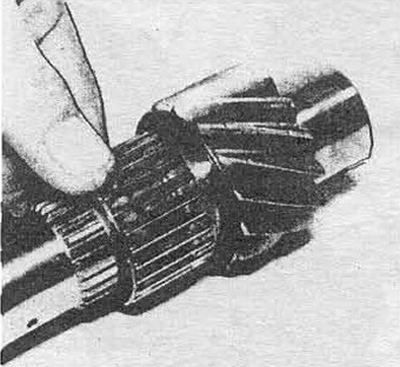

Pic. 6.56a Install the thrust washer on the intermediate shaft...

Fig 6.56b... and needle bearing

57. Install the first gear and synchronizer.

Pic. 6.57a Install the 1st gear

Pic. 6.57b... and synchronizer

58. Install the 1st/2nd gear synchronizer assembly (with reverse gear), synchronizer and spring, spacer and 2nd gear needle bearing.

Pic. 6.58a Install the 1st/2nd gear synchronizer assembly and spring

Pic. 6.586... spacer...

Pic. 6.58v... needle bearing

59. Install the second gear.

Pic. 6.59 Installing the second gear

60. Install the washer.

Pic. 6.60 Installing the washer

61. Install spacer and needle bearing.

Pic. 6.61a Installing the 3rd gear spacer

Pic. 6.61b... and needle bearing

62. Install the third gear.

Pic. 6.62 Installing the third gear

63. Install the synchronizer and spring.

Pic. 6.63 Fitting the synchronizer and spring

64. Install the 3rd/4th gear synchronizer assembly.

Pic. 6.64 Installing the 3rd/4th gear synchronizer assembly

65. Install the needle bearing.

Pic. 6.65 Fitting the needle bearing

66. Install the spring, synchronizer and 4th gear.

Pic. 6.66 Installing the spring, synchronizer and fourth gear

67. Install spacer with flange.

Pic. 6.67 Fitting the spacer with flange

68. Slightly tighten the spacer with the flange and measure the axial clearance in each gear. If any of the measurements are out of specification, replace the appropriate adjusting link as needed (washers and spacers).

Pic. 6.68a Measuring the axial clearance of the 1st gear gear

Pic. 6.686 Measuring the axial clearance of the 2nd gear gear

Pic. 6.68v Measuring the axial clearance of the 3rd gear gear

Pic. 6.68g 4th gear end play measurements

69. If you are assembling a 5-speed gearbox, install the 5th gear thrust washer on the secondary shaft, then the gear itself, the needle bearing and the synchronizer assembly. Slightly tighten the synchronizer sleeve and check the axial clearance in the gear. If the axial clearance is out of range, replace the thrust washer.

Parts Inspection

70. Inspect the box body and flywheel housing for cracks. especially in the areas of the bolt holes. Clear the magnetic trap.

71. Inspect the shafts for grooves, nicks, wear, and chipped gear teeth.

72. Check the bearings. They should rotate without rattling sounds and evenly. Always replace flywheel housing bearings if they have been removed.

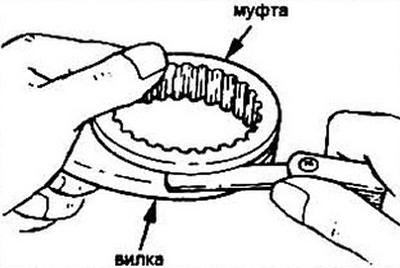

73. Check up a backlash in couple a plug/coupling of the synchronizer. If the clearance is greater than the allowable (given in specification) - replace the plug.

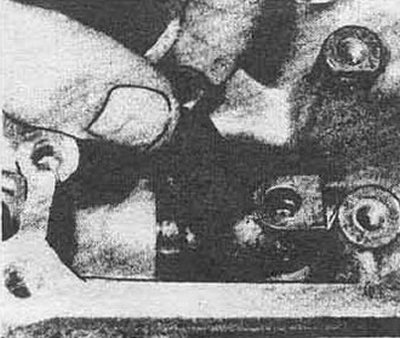

Pic. 6.73 Measuring the gap in a pair of synchronizer fork / sleeve

74. Press the synchronizer and engage it with the gear. Check by twisting the presence of a gap in the engagement - it should be minimal or completely absent (see specification data). Otherwise, replace the synchronizer.

Pic. 6.74 Checking the gap in the pair of synchroketor/sasterium

75. Deterioration of the synchronizer assembly with a guarantee provides noise when switching. Replace a worn synchronizer assembly.

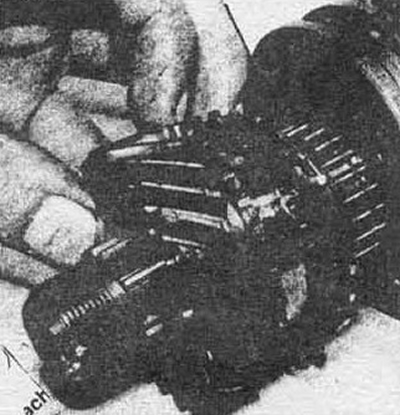

76. If you have disassembled the synchronizer assembly, pay attention to that. that the hub can only be installed in the coupling in one of the three positions determined by the main splines. Therefore, mark the relative position of the hub and bushing prior to disassembly.

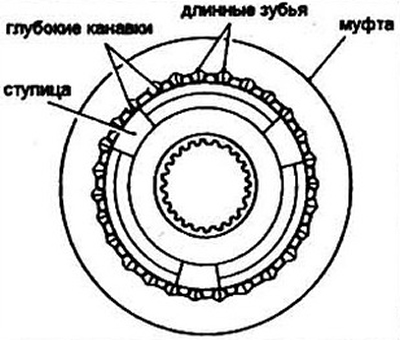

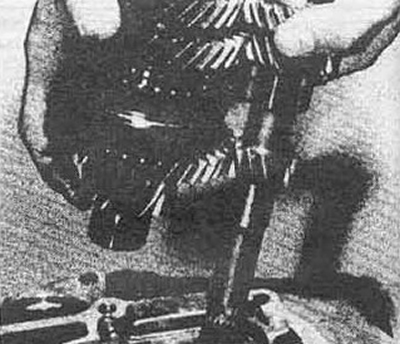

Pic. 6.76 Installing the synchronizer hub in its clutch

77. To disassemble the intermediate shaft, refer to steps 41-54. The secondary shaft is made as a single unit and is not subject to disassembly: if it is not suitable, it is replaced entirely.

78. When assembling, use new oil seals and seals. The same applies to the intermediate shaft mounting nut.

Main gear and differential repair

79. Follow steps 1-40 to gain access to the differential.

80. The differential and main gear do not usually break, however, it would be nice to inspect the integrity of the teeth on the gears and backlash.

81. Before disassembling the main gear / differential assembly, mark the position of the main gear driven gear relative to the differential, unscrew the bolts securing the driven gear. Attention: bolts with left-hand thread.

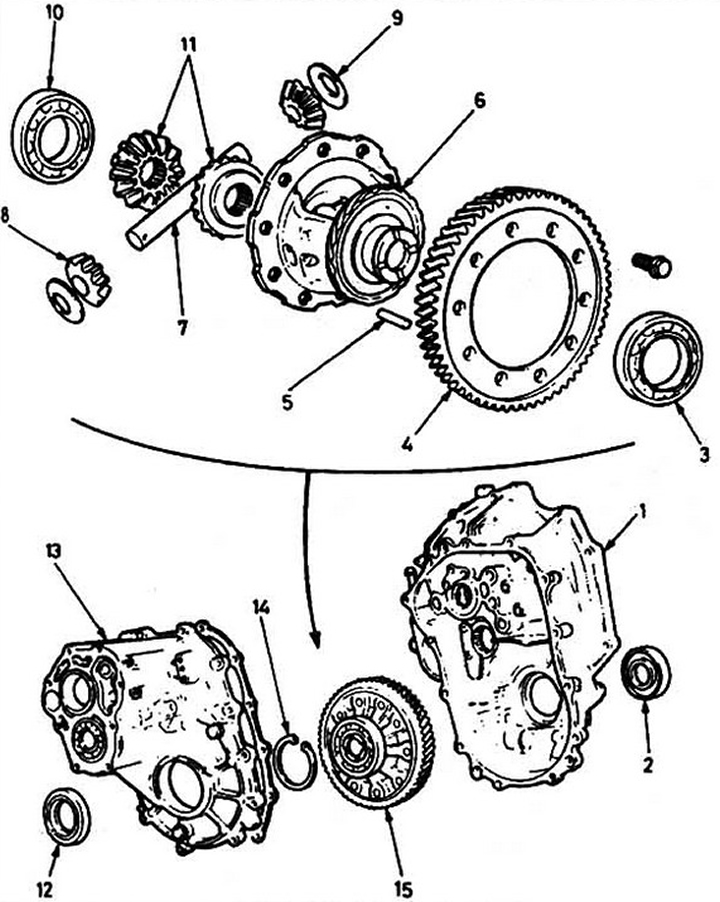

Pic. 6.81. Assembling the differential/final gear assembly 1 - clutch housing; 2 - stuffing box; 3 - bearing; 4 - driven gear of the main gear; 5 - pin; 7 - drive gear shaft; 8 - drive gear; 9 - thrust washer; 10 - bearing; 11 - side gear; 12 - stuffing box; 13 - box body; 14 - stopper; 15 - differential assembly.

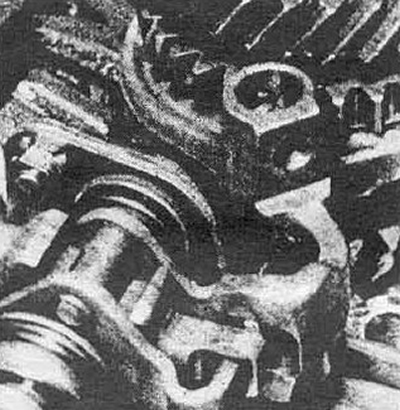

82. Remove the pin from the pinion shaft.

83. Lightly tap the shaft out of the differential housing.

84. Remove drive gears, thrust washers and side gears.

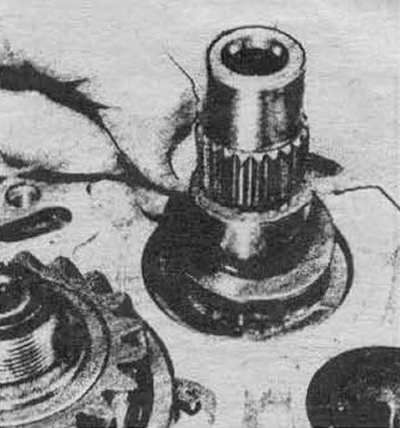

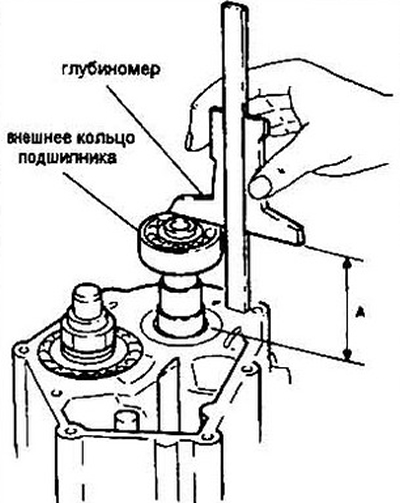

85. Using a suitable puller, remove the differential bearings.

86. Assembly is carried out in the reverse order. Only the inner rings of the bearings are pressed in.

87. When installing the driven gear of the final drive, position the notch on the flange towards the differential along the previously applied marks. Adjustment relative to the position of the main gear gears is carried out by adjusting washers.

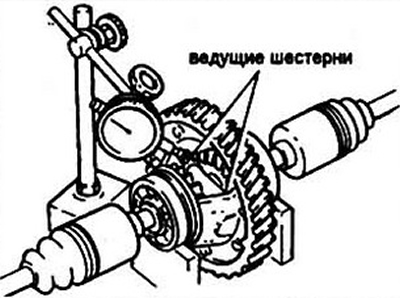

88. To adjust the clearance in the final drive gears, connect the drive axles. Place the differential cup in the V-stand and measure the play in the drive gears with a dial gauge. If the clearance is out of range (see specification), replace thrust washers.

Pic. 6.88 Measurement of clearances in the drive gears of the final drive. Connect drive axles

Assembly - five-speed gearbox

89. Install the bearing and output shaft seal in the flywheel housing.

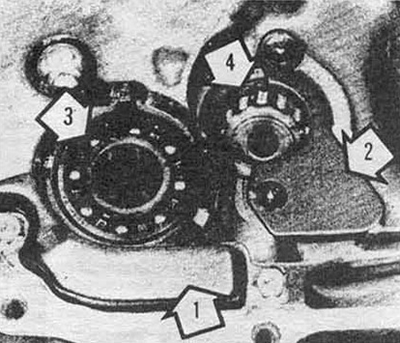

Pic. 6.89 Flywheel housing assembly: 1 - breather; 2 - bearing holder; 3 - secondary shaft bearing; 4 - intermediate shaft bearing

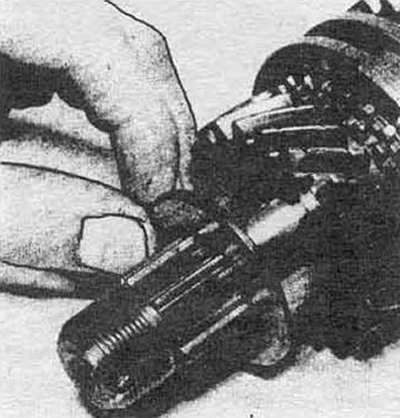

90. Install the breather on the flywheel housing.

91. Install the oil slinger.

92. Install the intermediate shaft bearing, bearing holder into the flywheel housing and tighten the holder mounting screws.

93. Install the speedometer drive shaft and secure it.

94. Establish an epiploon and anther of a shaft of switching.

95. If the differential bearings have been replaced, slide them slightly into the box housing until the circlips seat, then install the differential into the flywheel housing.

96. Connect the flywheel housing and the box housing and check the clearance between the circlip and the outer ring of the differential bearing. If the clearance is out of range (see specification), install a retaining ring of a different thickness (see specification).

Pic. 6.96 Checking the clearance between the outer ring of the bearing and the circlip

97. Remove the box housing and install the differential in the flywheel housing.

98. Insert the spring and shift lever retainer ball into the hole in the flywheel housing.

Pic. 6.98a Install the engagement shaft detent spring, then the ball

Pic. 6.98b... click on the ball...

Pic. 6.98v... and insert the shift shaft into the flywheel housing

Pic. 6.98 Install the shift lever on the inner end of the shaft...

Pic. 6.98d... push the shaft until it seats in the opposite boss. Tighten the bolt and fix it

99. Check the correct orientation of the shift lever and install the lever holder. Tighten the holder bolts to specification.

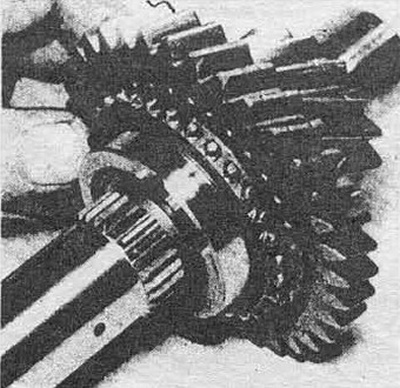

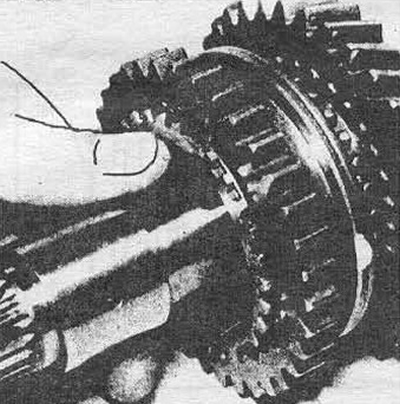

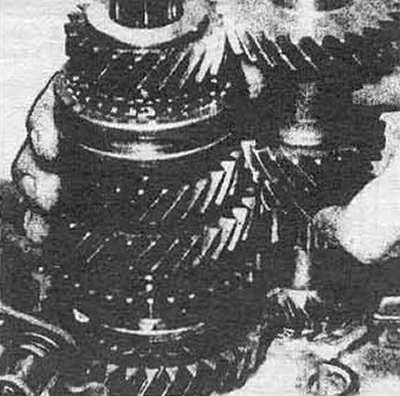

100. Simultaneously install the secondary and intermediate chambers, aligning their respective gears, into the flywheel housing.

Pic. 6.100a. Align the gears of the secondary and intermediate shafts...

Pic. 6.100b... and install them in the flywheel housing

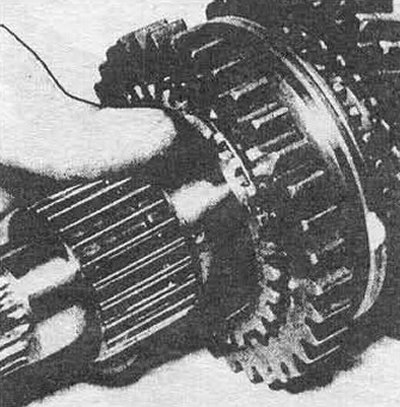

101. Slide the 1st/2nd synchro sliding clutch until it engages with the 2nd gear and install the shift fork into the clutch groove.

Pic. 6.101. Advance the 1st/2nd synchronizer clutch until it engages with the 2nd gear and insert the shift fork into the clutch groove

102. Install the 3rd/4th gear shaft and fork.

Pic. 6.102. Installing the 3rd/4th gear shift shaft and shift fork

103. Establish a shaft of inclusion of 1st/2nd transfers.

Pic. 6.103. Installation of a shaft of inclusion of 1st/2nd transfers

104. Orient the 5th/Reverse engagement latch and insert the engagement shaft through it.

Pic. 6.104. Orient the 5th/Reverse shift latch and insert the shift shaft through it

105. Make sure that the grooves of the retainers on the inclusion shafts enter the flywheel housing and are located towards the box body.

106. Tighten bolts of fastening of fork of shaft of inclusion of transfers, having placed new lock washers under bolts. Bend the locking tab of the washer.

Pic. 6.106. Tighten the fork mounting bolts on the shafts. Use only new lock washers. Firmly press the tongue of the new lock washer against the face of the bolt

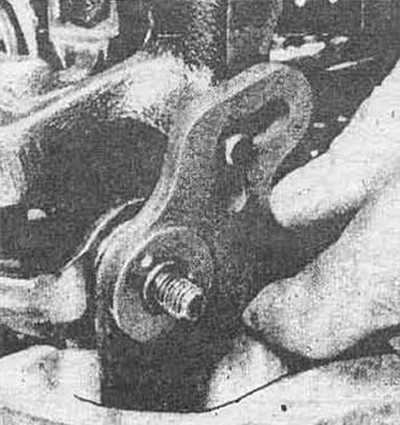

107. Install the reverse detent spring and ball, shift lever, special washer and nut.

Pic. 6.107a. Install the reverse detent spring, then the detent ball

Pic. 6.107b. Install the reverse gear lever, correctly orient it relative to the ball...

108. Install the reverse idle gear and shaft.

Pic. 6.108. Reverse Shaft and Idle Gear Installation

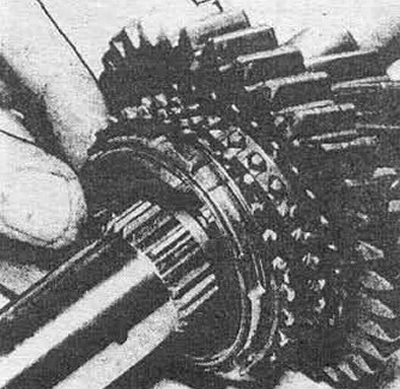

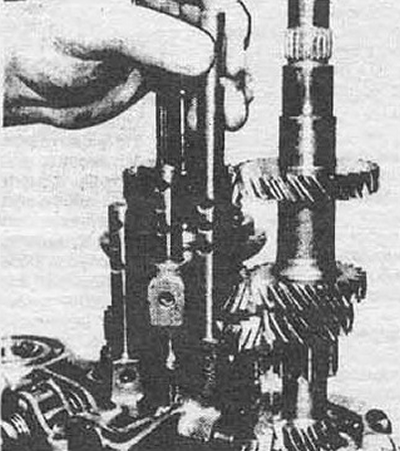

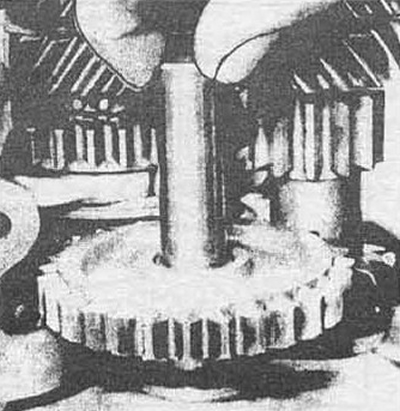

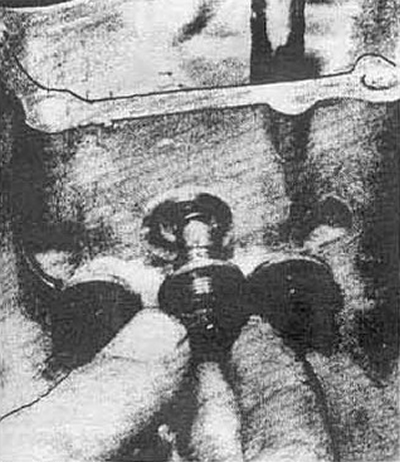

109. Install the bearings of the secondary and intermediate shafts, opening the retaining rings, in the box housing.

Pic. 6.109. Open the lock rings and insert the bearings of the secondary and intermediate shafts

110. Make sure the drive pins are in place in the box body. Apply sealing paste to the mating surface. Install the magnet.

111. Lightly oil the ends of the shafts and bearings of the differential to facilitate assembly of the gearbox housing and flywheel housing.

112. Pair the box body and the flywheel housing, install the bolts and tighten them to the torque given in the specification in the sequence shown in fig. 6.112 a, b.

Pic. 6.112. The order of tightening the bolts securing the box to the crankcase

113. Install breather hose and clutch cable bracket.

Pic. 6.113. Installing the breather hose and clutch cable bracket

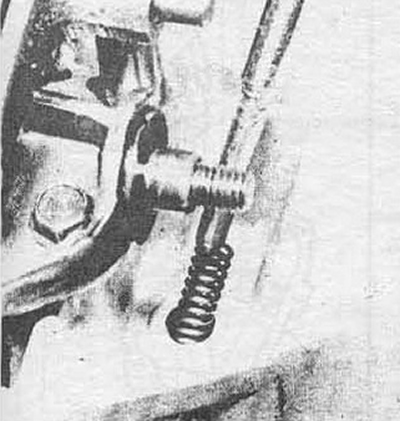

114. Install balls, springs and retainer caps.

Pic. 6.114. Install the retainer ball «the spring and tighten the plug

115. Install the 5th gear on the intermediate shaft with the boss towards the bearing.

Pic. 6.115. Installing the 5th gear

116. Install the Belleville washer with the notch toward the gear.

Pic. 6.116. Install the cup washer with the groove towards the gear

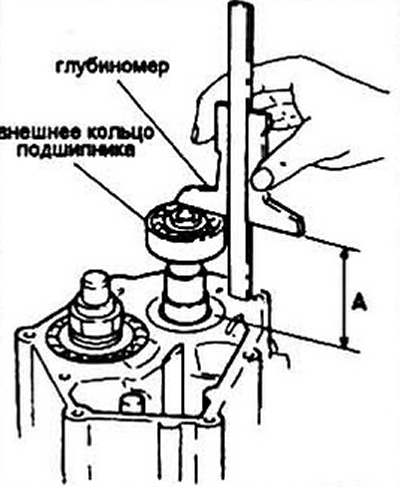

117. Establish a nave of the synchronizer of the fifth transfer on a secondary shaft. Using a depth gauge, measure height A. Take the average of three measurements around the circumference of the bearing.

Pic. 6.117. Bearing Height Measurement (dimension A is equal to the height of the back cover)

118. Remove the bearing and synchronizer hub from the output shaft. If you can no longer do this, remove the retaining ring, Belleville washer or oil flinger ring from the back cover.

Pic. 6.118a. Remove the stopper and belleville washer from the rear cover (early models)

Pic. 6.118b. Remove the stopper and oil slinger (later models)

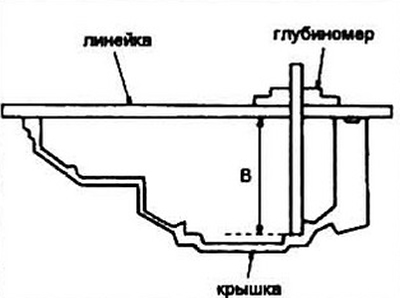

119. Lay a rigid ruler along the cover flange and use a depth gauge to measure distance B. Take the average of three measurements at equidistant points on the circlip seat and subtract the thickness of the ruler.

Pic. 6.119. Place a straight edge along the back cover flange and measure distance B

120. To calculate the thickness of the fifth gear lock ring, use the following formula.

- On early models: B - A - 0.85 = retaining ring thickness.

- Late models with oil flinger: B - A - 0.11... 0.18 = retaining ring thickness.

121. Install a Belleville washer or flinger into the back cover of the box, then install the stopper.

122. Install the 5th gear thrust washer, needle bearing and gear on the output shaft.

Pic. 6.122a. Install the 5th gear thrust washer...

Pic. 6.122b... needle bearing

Pic. 6.122v... and gear on the output shaft

123. Install the synchronizer and spring.

124. Install the synchronizer hub with the recess towards the gear

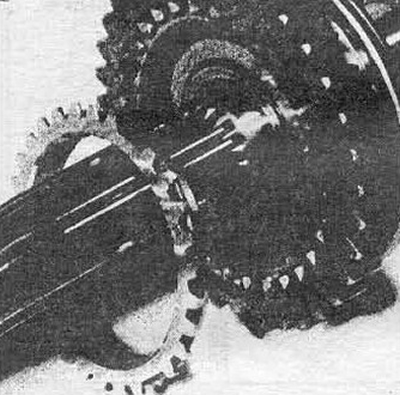

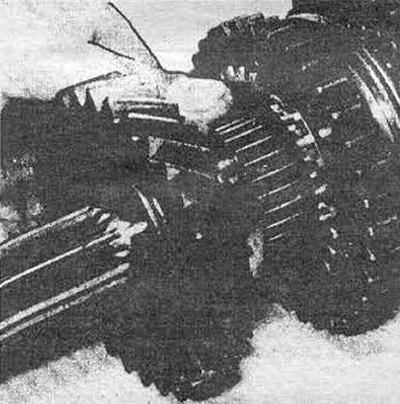

125. Engage the 5th gear fork with both» which synchronizer clutch (the notch is directed towards the gear) and install the yoke and coupling as a unit on the shaft. Remember that the coupling can only be installed on the hub with one side in one of the three positions of the main splines. Lower Clutch Synchronizer» down.

Pic. 6.125. Install the fifth gear fork into the groove of the synchronizer clutch and install them as one piece

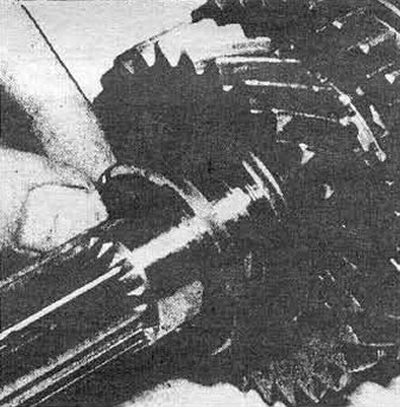

126. Take a new countershaft nut and tighten it to specification. Loosen the nut and re-tighten with the same torque. lock nut (see fig. 6.126).

127. Install the locking pin in the 5th gear fork.

Pic. 6.127. Insert the locking pin into the 5th gear fork

128. Install the output shaft bearing. The number engraved on the bearing ring should point towards you.

129. Apply sealing paste to the mating surface, ensure that the drive pins are present in the back cover, and install the cover. Tighten the bolts.

130. Establish the switch of a lamp of a backing.

131. Check the inclusion of all gears.

132. Install clutch release bearing (if it was taken).

Four-speed box

133. Do steps 89-114.

134. Establish the bearing of a secondary shaft and measure height A. Take an average of three measurements on a bearing circumference.

Pic. 6.134. Measuring the height of the input shaft bearing (size A)

135. Remove the bearing from the secondary shaft. Remove the stopper and remove the belleville washer or flinger from the rear cover if you have not already done so.

136. Calculate the desired retaining ring thickness using the formulas in steps 119-121.

137. Secure the intermediate shaft from turning and install a new lock nut. Tighten to specification, loosen and retighten. Lock the nut.

138. Apply sealing paste, ensure that the drive pins are in place, and secure the back cover.

139. Establish the switch of a lamp of a backing.

140. Check up correctness of inclusion of transfers.

141. Install clutch release bearing (if it was dismantled).