Pic. 18.1 Clean the oil passages with a wire brush and flush them

2. Check the main and connecting rod journals for signs of obvious wear, cracks, chips and scoring.

3. Draw the edge of the coin several times along the surface of the necks. If the surface is uneven, you will immediately feel it. In the case of an uneven surface, regrinding of the neck is required.

4. Deburr the crankshaft oil holes with a file.

Pic. 18.4 Chamfer oil holes: burrs will damage the bearing

5. Inspect the rest of the crankshaft for cracks.

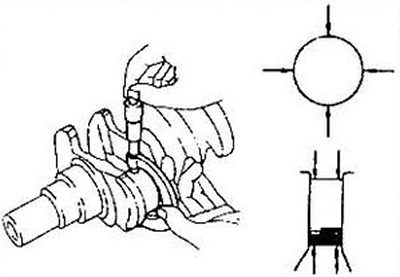

6. Using a micrometer, measure the diameters of the main and connecting rod journals and compare the results with the data in the specification. Take measurements at several points around the neck. Measure the journal diameter near the shaft webs to determine the taper.

Pic. 18.6 Measure the diameter of the necks at several points to determine taper and out-of-roundness

7. If the shaft journals are damaged, tapered or worn outside the allowable limits, then they are subject to regrinding to the repair size. Don't forget to purchase the appropriate repair inserts.

8. Inspect both ends of the shaft journal for wear and damage. If the oil seal has cut a groove in the neck, if there is a scratch or dent there, a new oil seal may not prevent oil from flowing. Repair of the necks under the stuffing box consists in pressing the repair sleeve.

If the shaft repair does not suit you, replace the old shaft with a new one.