2. If the valves are already installed, go directly to step 8.

3. Install spring seats on guide, install new seals on each valve guide. Keep in mind that the intake and exhaust valve seals are not interchangeable. The inlet valve seals have a white spring, the exhaust seals have a black one. With a hammer and mandrel (a suitable deep head can be used instead), carefully stuff the oil seal until it is fully seated on the guide. Do not twist or distort the gland during installation.

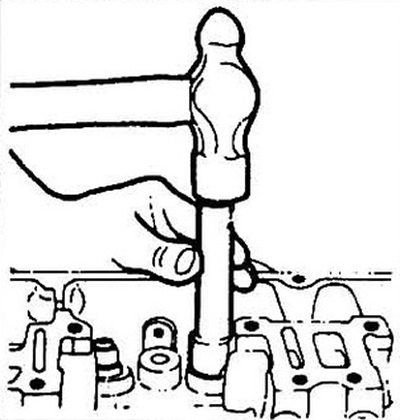

Pic. 11.3 Carefully press the valve stem seal onto the guide using a mandrel or deep socket

4. Lubricate the valve stem with engine oil and insert it into place.

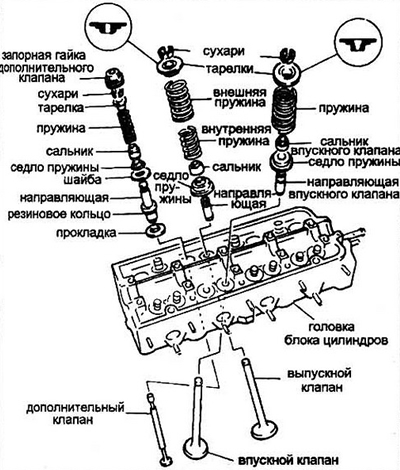

5. Install the springs and poppets, bearing in mind that the intake and exhaust valve poppets are not interchangeable.

Pic. 11.5a Cylinder head of engines with additional valves (prechamber)

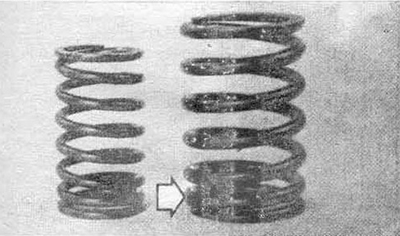

Pic. 11.5b Install the outer spring (on right) narrow part (arrow) to the cylinder head

The exhaust valve has two springs.

6. Compress the springs with a valve remover and install the crackers in the valve grooves, slowly release the spring and make sure the crackers are installed correctly. Lubricate the inside of the studs with grease to facilitate installation.

7. Repeat steps 4, 5, 6 for all valves. Put the valves back in place.

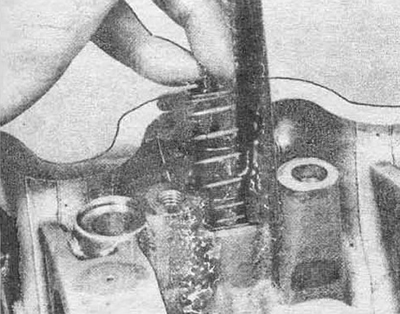

8. Check the height of the spring in the assembled state using a ruler or vernier caliper. Measure from the top of the spring seat to the bottom of the plate. If the height of the spring is greater than the recommended specification, add a washer.

Pic. 11.8 Measuring the spring height

Attention: never install a washer if the height of the spring is less than required.

9. Install the camshaft and rocker shaft assembly (see part A).