Withdrawal

1. The main brake cylinder is installed in the engine compartment on the brake booster housing.

2. Remove the brake fluid from the reservoir using a syringe.

3. Prepare rags and plugs for the pipes of the brake fluid reservoir.

Caution: Brake fluid can damage the painted surfaces of your vehicle.

4. Release nuts of fastening of brake tubes to the main brake cylinder. Use a wrench to prevent damage to the brake pipe nuts.

5. Carefully remove the brake pipes and plug the hole.

6. Disconnect the electrical connector, unscrew the nuts securing the cylinder to the brake booster. Remove the cylinder from the studs and remove from the vehicle.

Repair

7. Before repair, purchase a repair kit for this model of the brake master cylinder.

8. Release a collar of a tank of a brake liquid and remove a tank from the cylinder.

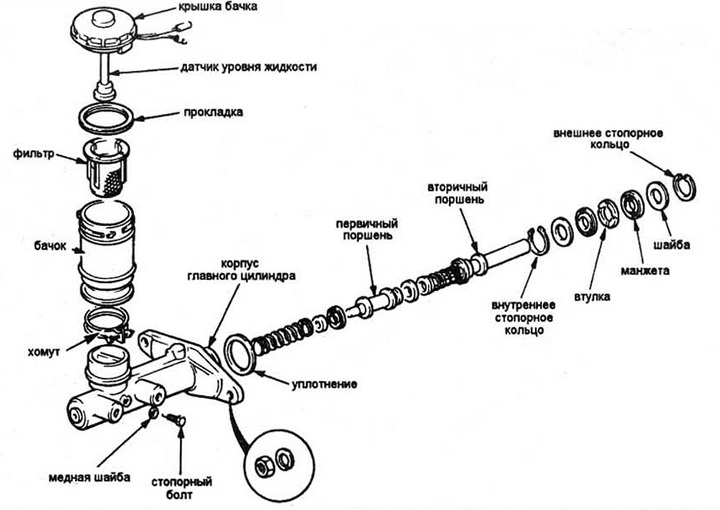

Pic. 7.8 Assembly of a typical brake master cylinder assembly

9. Remove the outer snap ring, washer, cap and bushing.

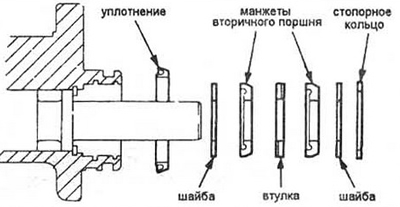

Pic. 7.9 How to disassemble the master cylinder

10. Fix the brake cylinder in a vise and using a beard or screwdriver, press the secondary piston all the way to the opposite end of the master cylinder. holding the piston in this position. remove the retaining bolt on the side of the cylinder.

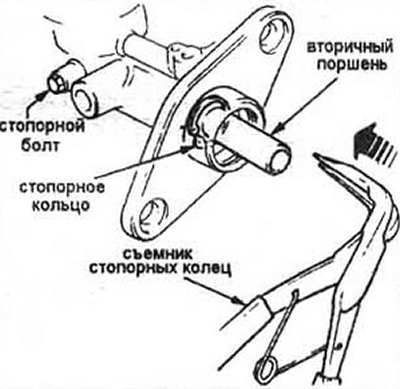

Pic. 7.10 Press down on the secondary piston and remove the retaining bolt and inner retaining ring

11. While holding the piston down, carefully remove the inner circlip.

12. Now you can dismantle all the internal parts of the brake cylinder. Remember the relative position of the components.

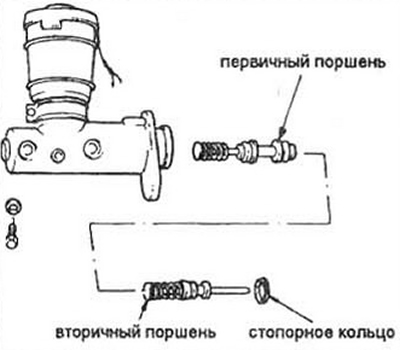

Pic. 7.12 Master cylinder disassembly

Attention: two springs have different characteristics, do not confuse them!

13. Carefully inspect the inner surface of the master cylinder. Any deep scratches or other damage require replacement of the entire cylinder.

14. Replace all the parts that are in the repair kit. Rinse other parts in clean brake fluid. During lubrication with a brake bone, fasten the joints.

15. Lower the assembled parts into the bore of the cylinder, press them to the lower end, install the lock bolt with a new copper washer.

16. Install a new inner circlip. Make sure it sits in the groove.

17. Lubricate the seal, secondary piston cups and bushing with brake fluid. Install them with washers (see fig. 7.9). Install locking ring.

18. Install the tank, securely fasten the clamp.

19. Before installing the master cylinder, it is recommended to pump it on the workbench. This is necessary to supply pressure to the master cylinder pistons. Bleed the master brake cylinder by securing it in a vice to the mounting flange.

20. Place the screw plugs in the inlet holes of the master cylinder in such a way that there is no air leakage and at the same time they can be easily unscrewed.

21. Fill the reservoir with brake fluid recommended for your vehicle (see chapter 1).

22. Turn away one plug and press the piston for removal of air from the main cylinder.

23. Screw on the plug and release the piston.

24. Repeat these operations until only brake fluid comes out of the hole. Then pump the second circuit in the same way. Periodically add brake fluid to the reservoir to compensate for leaks.

25. In the absence of suitable plugs, you can use your own finger. This is less convenient, but the result will be the same.

Installation

26. Install the brake cylinder on the brake booster studs and hand-tighten the fastening nuts.

27. Wrap brake pipes. Since the brake cylinder is not yet fixed, this allows you to correctly install the threads of the pipeline nuts.

28. Fully tighten the cylinder and brake pipe mounting nuts.

29. Fill the reservoir with brake fluid and bleed the brake system (see Section 10).