To hang the engine high enough to remove the subframe, you will need a hydraulic lift or a strong hoist and equipment to fix the raised engine.

Withdrawal

1. Mark the position of the hinges and remove the hood.

2. Remove the air filter and air ducts.

3. Remove the battery, tray, and relay rack.

4. Decompress the fuel system (Ch. 5).

5. Identify and disconnect from the engine cables, wire hoses, including cruise control and throttle cables, brake booster hose, fuel lines, intake manifold hoses, etc., except for cooling system hoses. First disconnect the clamps and brackets for fastening the wiring routes and cable sheaths.

6. Disconnect the wiring connectors from the engine processor unit. The unit is mounted in the footwell on the passenger side.

7. Get the wiring harnesses with seals through the wall of the engine compartment by unscrewing the seal flange bolts and turning the seals counterclockwise.

8. Disconnect the battery cable from the relay and fuse box.

9. Disconnect the engine bus to ground.

10. Remove drive belts. Remove the power steering pump, set aside and secure without disconnecting the hoses.

11. Disconnect the battery cable from the starter.

12. Lift the car, remove forward wheels and the bottom guard of the engine.

13. Drain the oil and fluid from the engine and transmission, drain the coolant..

14. Disconnect the oxygen sensor connector

15. Disconnect the exhaust pipe from the manifold and converter.

16. Disconnect the shock absorber fork from the lower suspension arm, unscrew the bolts and remove the fork from the suspension strut.

17. Disconnect the stabilizer links from the suspension arms.

18. Press the ball joints out of the suspension knuckles.

19. Disconnect the axle shafts and knock out the spline axles from the wheel hubs. Take the half shafts to the side and tie. Place plastic bags over splined axles and boots to keep dirt out.

20. Disconnect the cable from the gearbox by removing the cover and unscrewing the bolt on the drive lever.

21. Remove the clamps and remove the power steering hose from the front cross member of the subframe.

22. Turn away nuts of a support of transmission

23. Remove the subframe reinforcement brackets by unscrewing the bolts.

24. Remove the remaining hose clamps and wiring on the subframe.

25. Remove the steering gear from the cross member.

26. Turn away bolts of fastening of a back support of the engine/transmission.

27. Lower the car, disconnect the hoses from the radiator.

28. Disconnect the heater hoses from the engine.

29. Disconnect from the transmission and muffle the cooling hoses.

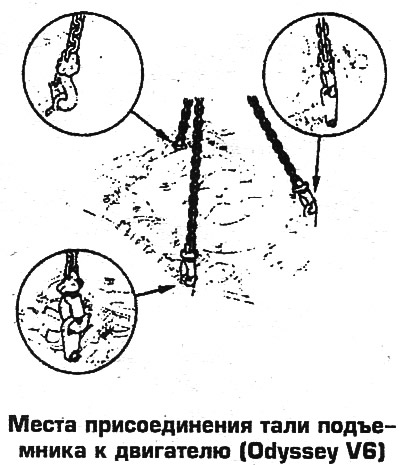

30. Attach a hoist to the engine (photo).

31. Remove the engine side support bracket.

32. Turn away a nut of an arm of a forward support.

33. Raise the car.

34. Pick up the slack in the waist.

35. Mark the location of the subframe relative to the body and the mounting location.

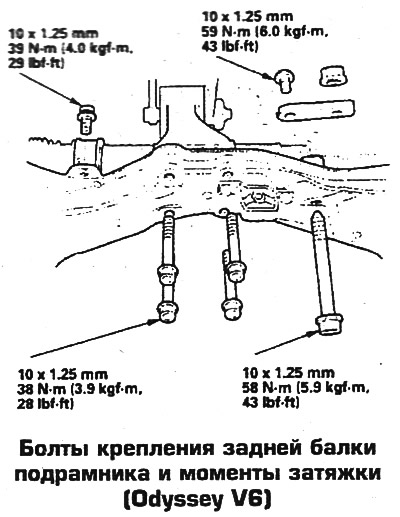

36. Remove the bolts and carefully lower the subframe.

37. Securely fasten the steering gear to the bottom of the body by tying it with a strong rope.

38. Turn away bolts and remove the conditioner compressor, without disconnecting hoses, take away the compressor aside and fix.

39. Make sure all hoses, wires and cables are disconnected from the power unit.

40. Lower the power unit and remove it from under the car.

41. Place stands under the front of the car and block the rear wheels. If the vehicle needs to be rolled after removing the engine, install the subframe and removed suspension parts

42. Remove the gearbox intermediate shaft.

43. Remove the cover in the transmission housing and, rotating the crankshaft, unscrew 8 torque converter fastening bolts one by one.

44. Remove the reinforcement plate, starter and unscrew the transmission mounting bolts.

45. Remove the transmission from the engine, making sure that the torque converter remains on the transmission. In case of sticking on the drive plate, move the torque converter through the starter window towards the transmission.

Installation

46. Install the transmission and tighten the bolts to 64 Nm.

47. Alternately wrap 8 bolts securing the torque converter to the drive disk, tighten the bolts in a diagonal order with a torque of 12 Nm.

48. Check the freedom of rotation of the crankshaft.

49. Check the torque of the crankshaft pulley bolt by holding the pulley with tool 07JAB-001020A or equivalent. The moment should be 245 Nm.

50. Establish an intermediate shaft, having replaced a spring ring.

51. Raise the car.

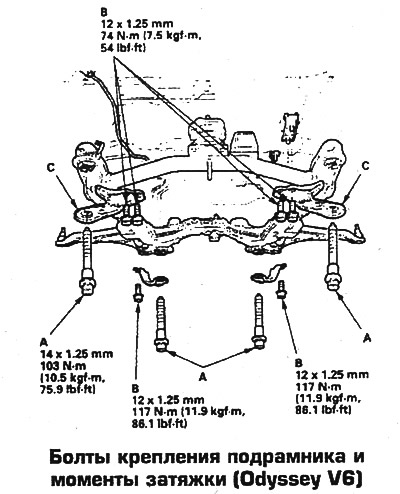

52. Install the power unit on the car by lifting it from the bottom of the car.

53. Install the air conditioning compressor, tighten the bolts with a torque of 22 Nm.

54. Install the subframe, aligning the marks made during disassembly, tighten the bolts to the torque indicated on the subframe.

55. Install the transmission support brackets on the subframe, tighten the nuts with a torque of 38 Nm.

56. Install the rear support of the power unit, tighten the bolts with a torque of 38 Nm.

57. Wrap the nut of the front support, tighten the nut with a torque of 54 Nm.

58. Install the engine side mounts, tighten the mount bracket bolts to 44 Nm, then tighten the mount through bolt to 54 Nm.

59. Remove the hoist.

60. Install the steering mechanism, tighten the bolts with a torque of 38 Nm.

61. Lay the hydraulic booster hose and wiring in place, secure along the route with clamps.

62. Install the stiffeners of the subframe, tighten the bolts with a torque of 58 Nm.

63. Install the axle shafts and the removed and disconnected suspension parts.

64. Install the exhaust pipe, replacing the gaskets. Connect the oxygen sensor connector, install the bottom shield.

65. Lower the car.

66. Install all removed parts and assemblies, attach wires, cables and hoses according to the marks made during disassembly. Adjust straps and cables. If a new power steering pump belt is installed, then adjust it so that the deflection is 8.5-11 mm. After 5 minutes of running the engine, adjust the belt to normal tension (Ch. 1). Fill the engine and transmission with oil and fluids.

67. Before starting the engine, turn the ignition key to the RUN position, but do not start the engine. After waiting 2 seconds, turn off the ignition 2-3 times and turn it on again (this is necessary to fill the line with gasoline. Make sure there is no fuel leakage from the fittings.

|  |

|  |