2. Raise the car and remove the wheel.

3. Remove the caliper. Loosen the bolts and remove the caliper bracket.

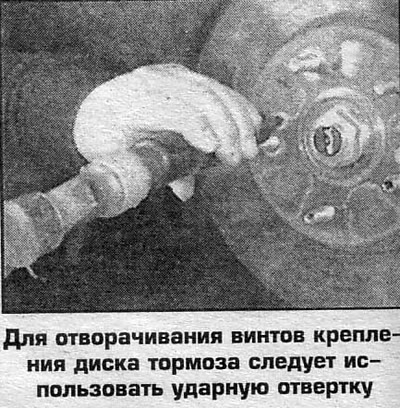

4. Loosen the screws and remove the drive by hand-feeding it off the studs. If the disc cannot be removed, then screw 2 bolts 8x1.25 into the threaded holes of the disc and, turning the bolts, remove the disc.

5. Installation is carried out in the reverse order. Separate the pistons in the caliper before installing the pads. When finished, depress the brake pedal to press the pads against the disc.

Examination

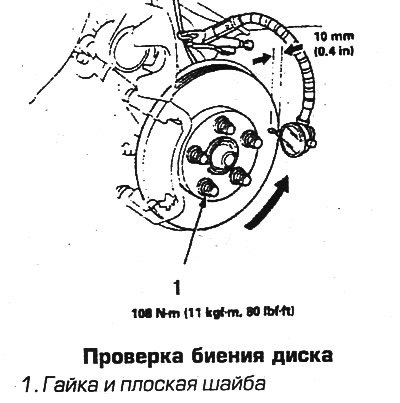

Check the runout of the hub with the disc removed, which should be no more than 0.05 mm. If the runout exceeds the norm, then replace the hub. The value of the maximum allowable thickness is cast on the disc. If after grinding the thickness is less than this value, then replace the disc. Check disc thickness, thickness uniformity and runout. To check the runout of the brake disc, remove the pads. After removing the wheel, tighten the wheel nuts and tighten them to 108 Nm. Check disk status (measurements are taken only on the disk without noticeable damage) and install a dial indicator and rotate the dial to check for runout. If the runout is greater than 0.10 mm, check the disc thickness. If the thickness is more than the maximum allowable, then grind the Disc with a special sandpaper without removing it from the car.

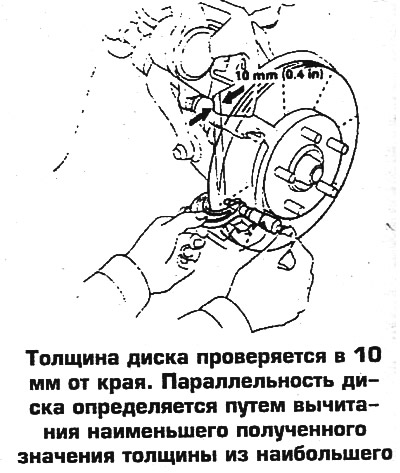

Disc thickness is checked 10 mm from the edge, every 45° (1/8 turn). Drive Parallelism (uniformity in thickness) determined by subtracting the smallest thickness value obtained from the largest. If unevenness exceeds 0.015 mm, grind the disc. If after grinding the thickness is less than the maximum allowable, then replace the disc.

|  |

|  |

|  |

|  |