Note. If defects in the protective cover are detected, the condition of the corresponding CV joint must be carefully studied. Often, fully remanufactured driveshaft assemblies can be purchased on a trade-in basis, which greatly simplifies the situation and saves time. Before proceeding with the dismantling of components, conduct marketing by finding out the prices of the necessary parts. Compare them with the cost of purchasing refurbished builds.

In car accessories stores, you can find split protective covers for CV joints. The installation of such covers does not require the dismantling of the shaft from the car, which in principle is very convenient. However, the compilers of this Guide still recommend removing the shafts to check the condition of the CV joints and stuff them with fresh grease.

1. Remove the drive shaft (see Section Removal and installation of power shafts).

2. Clamp the removed shaft in a vise with soft jaws.

Internal CV joint

Disassembly

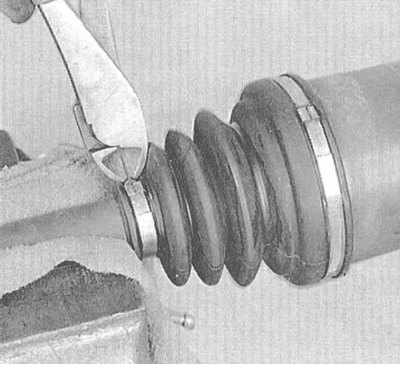

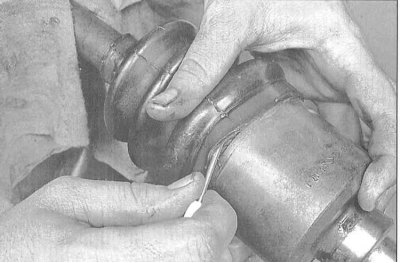

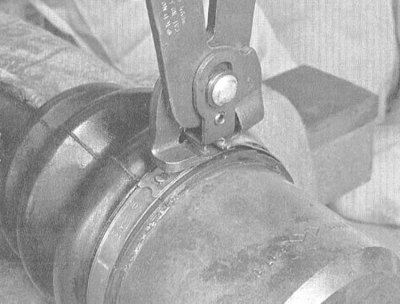

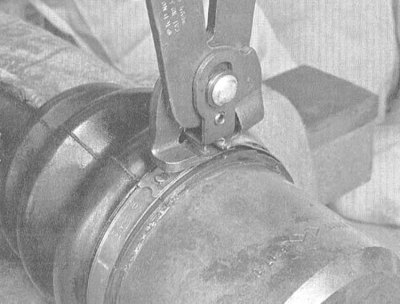

1. Evaluate the external condition of the protective cover of the CV joint; if there is the slightest doubt, the cover should be replaced. Cut off the bandage straps of the cover fastening and slide the latter from the hinge to the center of the shaft.

|  |

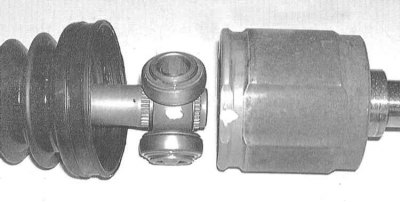

2. After carefully wiping the components, paint or use a scriber to mark the position of the tripod bearing assembly in relation to the outer race of the hinge. Remove the race from the bearing.

3. Remove the circlip from the outer shaft stud.

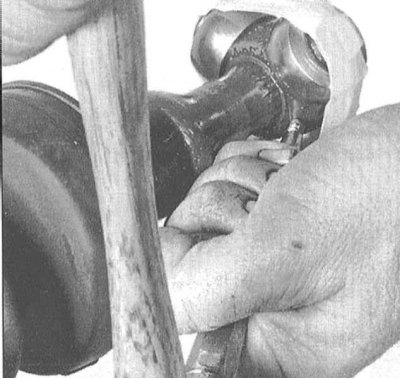

4. Secure the bearing rollers with tape, then knock the tripod assembly off the shaft using a hammer and brass drift.

5. Remove the circlip and remove the old protective cover from the drive shaft.

Examination

1. Carefully remove any traces of grease from the outer race of the hinge and the cavities of the tripod bearing. One by one, so as not to confuse, remove each of the sections of the tripod assembly and wash the rollers of the needle bearings with solvent.

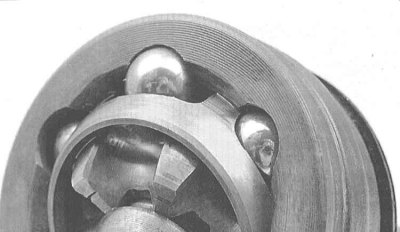

2. Check the rollers, bearings, the bearing part of the tripod assembly and the outer race of the hinge for signs of excessive wear of cavities, scoring, cracks and other mechanical damage. If necessary, replace the CV joint.

Assembly

1. Wrap the splines of the drive shaft pin with tape to protect the new CV joint boot from cuts.

2. Put the cover on the shaft, remove the tape and fit the inner retaining ring.

3. Place the tripod assembly on the shaft.

4. Secure the tripod assembly with the outer retaining ring.

5. Lubricate the inside of the needle roller bearings with special grease to temporarily fix them to the bearing members of the tripod assembly. Make sure that each roller is installed strictly in its original place.

Note. If the rollers are equipped with a rectangular flat, make sure that they are installed with this flat to the shaft.

6. Fill the outer race of the pivot halfway with the grease supplied with the new boot. Stuff the cover with the rest of the grease. Install the outer race on the shaft. Follow the correct alignment of the marks of the relative position of the cage and the tripod bearing made during the dismantling process.

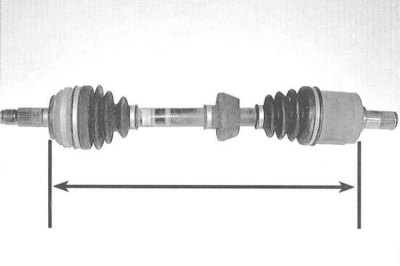

7. Insert boot lips into grooves on joint outer race and shaft body, then adjust shaft assembly length to specification.

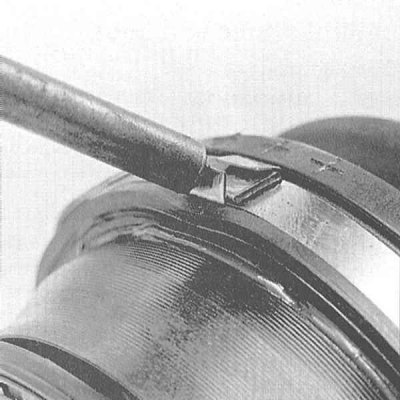

8. Having set the length of the shaft, release the air from under the cover by prying its outer (larger diameter) edge with a blunt screwdriver. Be careful not to damage the case.

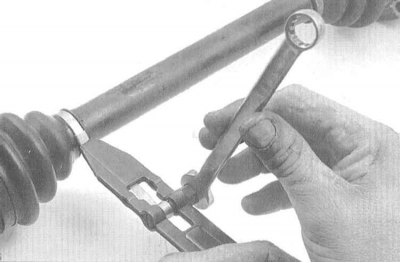

9. Fasten the cover with new bandage tapes / clamps.

|  |

|  |

10. Install the shaft assembly on the vehicle (see Section Removal and installation of power shafts).

Outer CV joint

Disassembly

1. Acting in accordance with the instructions set out in paragraphs with 1- 5, remove the inner CV joint from the drive shaft and disassemble it.

2. If the shaft is equipped with a dynamic damper, mark with paint the position of the outer edge of the damper assembly relative to the shaft, then cut the yoke and remove the damper.

Note. When replacing components, it is necessary to ensure that the distance between the inner CV joint boot and the damper is maintained (see specs).

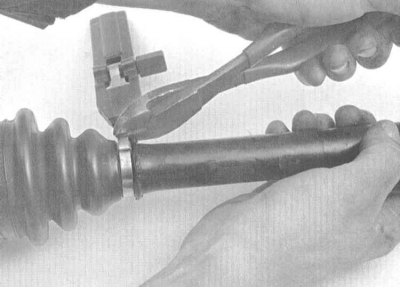

3. Cut off the bandage tapes and remove the SHRUS protective cover from the shaft.

Note. The outer CV joint cannot be disassembled and removed from the shaft.

Examination

1. Thoroughly wash the inner and outer CV joints with solvent, then dry them with compressed air.

Attention! Remember to wear protective goggles when using compressed air!

Since the outer CV joint cannot be disassembled, removing traces of old grease and solvent from it is associated with certain difficulties, but must be done in the most careful way.

2. Turning the hinge cover at various angles, carefully examine the condition of the balls, races and bearing cage. If defects are found, replace the shaft assembly.

Assembly

1. Wrap the splines of the drive shaft pin with tape to protect the new CV joint boot from cuts. Put the cover on the shaft, remove the adhesive tape, then stuff the grease supplied in the repair kit into the cover. Bring the cover into working position and fix it with new bandage tapes.

|  |

2. With the appropriate vehicle configuration, fit a dynamic load damper on the shaft. Make sure that the outer edge of the damper is placed in accordance with the marks made during the dismantling process.

Note. When replacing the outer joint shaft assembly, the damper is aligned with the protective boot of the outer CV joint in accordance with the results of the measurement made in paragraph 20.

3. Wash and assemble the inner CV joint assembly (see paragraphs 8 to 17). Install the drive shaft assembly to the vehicle (see Section Removal and installation of power shafts).