Examination

Disconnect its knock sensor electrical connector and drain coolant from the engine (see chapter Settings and ongoing maintenance). Remove the knock sensor from the engine block. Reconnect the connector to the sensor. Checking sensors of this type is carried out by registering voltage fluctuations on a voltmeter. Switch the meter to the low AC voltage scale. Connect the negative probe of the meter to the sensor body, the positive probe to the contact terminal. Lightly tap the bottom of the sensor with a hammer to simulate vibration. If the voltmeter does not register voltage fluctuations, the sensor should be replaced.

Note. In principle, this check can be made without removing the sensor from the engine.

Replacement

Attention! Wait until the engine has completely cooled down before proceeding with the procedure.

1. Disconnect the negative cable from the battery.

Attention! If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

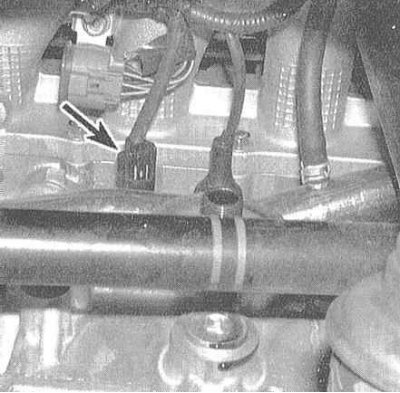

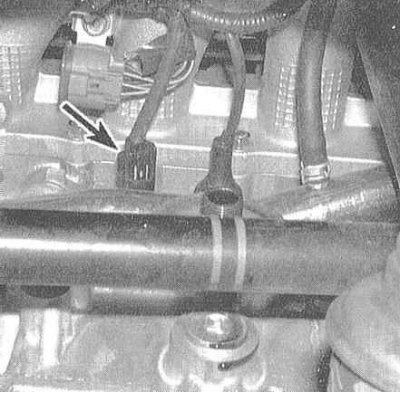

2. The knock sensor is screwed into the channel of the cooling path of the engine block and its eversion is associated with certain losses of coolant, which can be avoided by emptying the block in advance (see chapter Settings and ongoing maintenance). Disconnect the electrical connector and remove the sensor from the engine.

3. New sensors are usually shipped with anti-seize coated threads. Screw the replacement sensor into place and tighten it to the required torque (about 19 Nm).

Note. Overtightening the knock sensor can permanently damage it. Connect the wiring to the sensor and charge the cooling system (see chapter Settings and ongoing maintenance). Check the engine for signs of coolant leaks.