The best way out in this situation is not to rush, but to start collecting your set from those tools that will be used most often. Do not be fooled by the low price of tools when buying, sometimes it is much better to spend a little more, but win in quality.

A small number of tools, plus a bit of skill with them, is what it takes to get started. The basic set of any mechanic consists of wrenches, socket and torque wrenches. In addition to the normal assortment of screwdrivers, wire cutters and pliers, you should have the following tools for routine maintenance of your vehicle (virtually every fastener on your Accord or Prelude is metric):

- 1. Wrenches, socket wrenches and their combinations with sizes from 3 mm to 19 mm, and candle cartridges (20.6 cm or 15.9 cm). If possible, purchase socket wrench drivers of various lengths.

- 2. Stands to support the vehicle.

- 3. Oil filter wrench.

- 4. Groove or funnel for filling oil.

- 5. Small oiler and syringe (s) for lubrication injection.

- 6. Hydrometer for checking the battery.

- 7. Low-sided flat oil drain pan.

- 8. A large amount of rags for wiping.

In addition to the above things, there are a few other things that are not so absolutely necessary, but would be handy to have on hand. They include a spill absorbent pad, transmission fluid funnel, and commonly used lubricants, antifreeze, and fluids, although these can be purchased on an as-needed basis. This is a basic list for general maintenance, but only your personal needs and desires can accurately determine the complete list of required tools. After doing a few jobs on the car, you'll be amazed at the other tools and items on your workbench. Some common household items would be useful nearby: a siphon, empty coffee cans, a skein of twine, duct tape for mounting, small rolls of colored marking tape, markers and pens, a strong magnet, and a small mirror (for inspection under the manifold).

The second list of tools is for adjustments. Since these tools are not much more complex, they should not be prohibitively expensive. A basic list of control equipment could include:

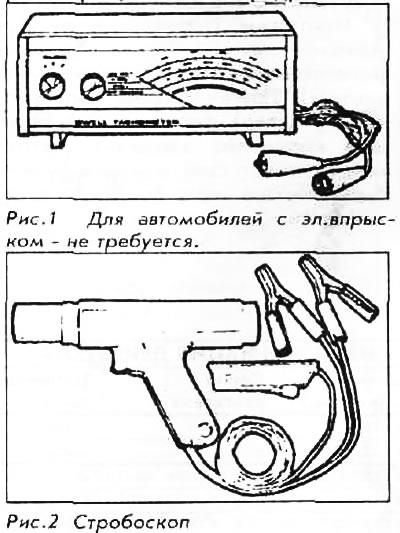

1. A device for determining the speed of rotation of the shaft in degrees.

2. Candle key.

3. Strobe (battery power is the best, although it will work from a regular 220V outlet). It will save some time, allowing you to examine the highlighted object faster than if it were disconnected and removed.

4. Measuring and adjusting tools for spark plugs.

5. A set of feeler gauges for adjusting the gap of the spark plugs.

In addition to these basic tools, there are several other tools and gauges that you will find useful. This:

1. Compressometer. Screw-in type - slower in use, but eliminates the possibility of erroneous measurement due to pressure relief. Indented type - faster, but less accurate. And yet, the indented type is not suitable for use on certain types of engines with a deeply machined spark plug hole.

2. Manifold vacuum gauge.

3. Test light.

4. Induction meter. Used to determine whether or not there is current in the wire. It is useful if there is a break in the bundled wire.

5. In the age of electronics, almost any diagnostic can not do without a voltmeter or ohmmeter. Fortunately, they are often combined into one volt-ohmmeter. The analog type with pointer pointer is suitable for most diagnostic work. But if you need to work on a whole block or circuit, you will need a high-resistance digital volt-ohmmeter.

As a final note, you'll probably find that a torque wrench is needed for just about everything, but it's primarily needed for basic work. Regular, radial wrenches are fine, although the more modern shear wrenches are more accurate and you don't have to twist your neck to look at torque. The break wrench is more expensive and requires periodic calibration.

A good torque wrench will be deservedly expensive. If it has already been purchased, handle it carefully. Its accuracy may be impaired by throws or other forms of "vandalism". Keep him away until you need him. Also, do not use a torque wrench for tightening that does not require precise torque - a regular ratchet will do here.

The torque value for each fastener will be specified for those procedures where required. Unless otherwise specified, use the following values as a guide, based on the size of the fastener:

Bolts 6T

- 6 mm bolt/nut - 4-5 Nm

- 8 mm bolt/nut - 9-13 Nm

- 10 mm bolt/nut - 17-25 Nm

- 12 mm bolt/nut - 30-44 Nm

- 14 mm bolt/nut - 41-56 Nm

Bolts 8T

- 6 mm bolt/nut - 4-7 Nm

- 8 mm bolt/nut - 10-15 Nm

- 10 mm bolt/nut - 20-30 Nm

- 12 mm bolt/nut - 34-51 Nm

- 14 mm bolt/nut - 55-75 Nm